Direct Metal Laser-Sintering (DMLS), a layer manufacturing process, first originated as a method of rapid tooling and rapid prototyping. It has advanced via a multitude of innovations to be the key technology for e-Manufacturing, the fast and cost-effective direct production from electronic data. Sirona Dental Systems uses laser-sintering to manufacture customized series products out of metal. The firm has been producing dental prostheses in a special cobalt-chrome alloy, which has increased the efficiency of dental laboratories.

Direct Metal Laser-Sintering (DMLS), a layer manufacturing process, first originated as a method of rapid tooling and rapid prototyping. It has advanced via a multitude of innovations to be the key technology for e-Manufacturing, the fast and cost-effective direct production from electronic data. Sirona Dental Systems uses laser-sintering to manufacture customized series products out of metal. The firm has been producing dental prostheses in a special cobalt-chrome alloy, which has increased the efficiency of dental laboratories.

When Dr. Günter Saliger goes to the dentist, his thoughts revolve around the issues of process optimization and materials development. And for a good reason; the physicist works in the CAD/CAM division at Sirona Dental Systems, one of the leading manufacturers in the field of dental technology. He is responsible for the production service infiniDent. The name represents a unique range of services offered in which Saliger and his team of eight assume the role of extended workbench for dental laboratories throughout Europe. Since 2004, with modern technology and special production facilities, they have been making crown copings and bridges out of ceramic materials such as zirconium oxide and aluminium oxide on behalf of dental laboratory technicians. The fact that, since summer of this year, infiniDent’s fabrication center can now manufacture dental prostheses out of metal is tantamount to a mini revolution.

This breakthrough has been made possible by a close collaboration with the German systems manufacturer EOS (Electro Optical Systems). The company, whose headquarters are located in Krailling in Bavaria, is the leading representative of laser-sintering technology. It delivers complete systems solutions to key industries such as the medical technology, aerospace and automotive. Originally, the EOS machines were implemented for rapid prototyping and rapid tooling in the context of development processes. Today the trend is moving towards batch-sized optimized series production—e-Manufacturing. In the area of plastics, laser-sintering based e-Manufacturing is very much an established term. In the manufacture of metal parts it is just beginning to gain a foothold as a replacement process – for example as a clean, efficient alternative to casting. And that is exactly the crucial point in the case of Sirona.

This breakthrough has been made possible by a close collaboration with the German systems manufacturer EOS (Electro Optical Systems). The company, whose headquarters are located in Krailling in Bavaria, is the leading representative of laser-sintering technology. It delivers complete systems solutions to key industries such as the medical technology, aerospace and automotive. Originally, the EOS machines were implemented for rapid prototyping and rapid tooling in the context of development processes. Today the trend is moving towards batch-sized optimized series production—e-Manufacturing. In the area of plastics, laser-sintering based e-Manufacturing is very much an established term. In the manufacture of metal parts it is just beginning to gain a foothold as a replacement process – for example as a clean, efficient alternative to casting. And that is exactly the crucial point in the case of Sirona.

The end of casting

While casting, with all its laborious pre- and post-processing, used to be the only relevant molding process for metal dental prostheses, A brief peer into the build chamber of the laser sintering machine: Dr. Günter Saliger, Director of the infiniDent project at Sirona Dental Systems in Bensheim. “The Clean Alternative”, EOS at Sirona. November 2006 The end of casting: whereas the moulded prosthesis has to be laboriously post-processed, the laser-sintered bridge leaves the machine almost “ready to use”. Dental laboratories can now choose laser sintering from the range of services offered by infiniDent. “We are now virtually relieving the dental laboratory technician of the messy part of the work. He no longer needs to spend time mounting, embedding, casting or even deflasking and cleaning a mold, but instead can concentrate on core competences such as the ceramic veneering of the metal framework,” explains Günter Saliger. Precisely this framework – the anatomically static base construction of the dental prosthesis – is made at infiniDent’s fabrication center with the help of Direct Metal Laser-Sintering (DMLS). Here, the EOSINT M 270 technology comes into use, processing a bio-compatible cobalt-chrome alloy (inCoris NP), which EOS has developed specifically for dental prostheses on the basis of input from the dental laboratory technicians at Sirona.

Laser-sintering is a layer manufacturing process, which—depending on size and geometry—can economically manufacture small to large series. In this process, the products are directly built up 100 percent dense—without any molding tools whatsoever—in a generative process where layers of powder material are fused by a laser beam positioned via precision optics. The necessary technical control data for the laser technique are generated from geometric data using well known 3D-CAD programs such as Solid Works, ProEngineer, Catia and AutoCAD.

Laser-sintering is a layer manufacturing process, which—depending on size and geometry—can economically manufacture small to large series. In this process, the products are directly built up 100 percent dense—without any molding tools whatsoever—in a generative process where layers of powder material are fused by a laser beam positioned via precision optics. The necessary technical control data for the laser technique are generated from geometric data using well known 3D-CAD programs such as Solid Works, ProEngineer, Catia and AutoCAD.

Dental direct manufacturing

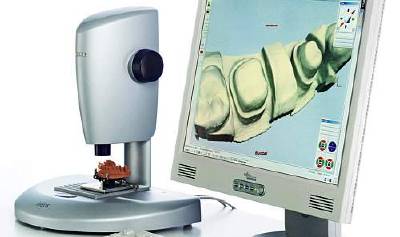

In dental technology, the control data comes from Sirona’s CAD/CAM system, inlab/inEos, which is widely used in dental laboratories in Germany. This process-oriented, complete solution is made up of, among other things, a modern 3D scanner (inEos) and an efficient 3D CAD program (inLab 3D). The scanner digitizes the plaster castings made from the individual patient’s teeth impressions. Using the CAD program, the dental laboratory technician (re)constructs the framework for the metal prosthesis on-screen. The CAD data The infiniDent process: Lasersintering relieves the dental technician from the “messy” part of the work. “The Clean Alternative”, EOS at Sirona. November 2006 resulting from this is then sent to infiniDent’s fabrication center via Internet. One of Sirona’s technicians checks the received data for its completeness and prepares it for lasersintering and then transfers it to the control unit of the EOSINT M 270. Once there are a sufficient number of crown copings and bridge frameworks for a job lot, the laser immediately starts production. Layer-by-layer and in a period of only a few hours, the machine produces several hundred dental prostheses out of the cobalt-chrome powder. The build speed is approximately three minutes per crown.

Up to and in excess of 80,000 units per year can be produced like this on a machine, whereby it is possible with laser-sintering to produce bridges with up to six elements. And the delivery time from order receipt is just three days at most. Those are three days that the dental laboratory gains for processing further orders. “The throughput times decrease to a minimum through the use of laser-sintering technology. That is comparable to an enormous increase in productivity and a definite technological advance for the dental laboratory”, says infiniDent’s manager Saliger. In comparison, while an experienced dental laboratory technician can produce about ten crowns in one working day, many hundreds of frameworks can be created on a laser-sintering machine – always of the same consistently high quality. And they are made at an unbeatable unit price of only $25.00 each.

“There is currently nothing that can match the EOSINT M 270 as the technological heart of infiniDent’s e-Manufacturing process. From the point of view of cost-effectiveness, Direct Metal Laser-Sintering (DMLS) is way ahead of casting and even mechanical production,” Saliger stresses. The available capacity inside the machine (10 x 10 x 9 inches) provides sufficient space to build hundreds of crowns and bridges in one job lot. With layer thicknesses of only 20 micron and the precision-focused laser, even the most intricate of geometries and complex structures can be reproduced exactly. These are arguments which also make DMLS interesting for applications outside of medical technology. In many cases, the slight roughness of the parts’ surfaces is a great advantage. For example, in the infiniDent process this improves the adhesion between the cobaltchrome of the dental prosthesis framework and the subsequent layering with ceramic.

“There is currently nothing that can match the EOSINT M 270 as the technological heart of infiniDent’s e-Manufacturing process. From the point of view of cost-effectiveness, Direct Metal Laser-Sintering (DMLS) is way ahead of casting and even mechanical production,” Saliger stresses. The available capacity inside the machine (10 x 10 x 9 inches) provides sufficient space to build hundreds of crowns and bridges in one job lot. With layer thicknesses of only 20 micron and the precision-focused laser, even the most intricate of geometries and complex structures can be reproduced exactly. These are arguments which also make DMLS interesting for applications outside of medical technology. In many cases, the slight roughness of the parts’ surfaces is a great advantage. For example, in the infiniDent process this improves the adhesion between the cobaltchrome of the dental prosthesis framework and the subsequent layering with ceramic.

One-offs in series

The Sirona example underlines the trendsetting significance of Direct Metal Laser- Sintering for the advancement of e-Manufacturing in dental technology. Yet, at the same time, the infiniDent project highlights the really fascinating element of the process, the cost-effective manufacture of series products of a very individual nature. After all, no two dental prostheses are alike. But even though each part is unique, it can be produced inexpensively and efficiently in series. For this reason alone, laser-sintering could become increasingly attractive for many other specialist areas of medical and orthopaedic technology.

The future role that the process will play, as an alternative for series production of metal parts in other industries, depends greatly on the development of different metal materials. These will need to meet the ever-increasing demands in strength, temperature resistance and accuracy. Recognizing this dependency, EOS is working with industry to rapidly develop new materials. In September, stainless steel, a new DMLS material, came onto the market, and titanium will follow in the early part of 2007. Meanwhile, a number of developers are already conducting research into the next—currently secret—solution.

EOS and e-Manufacturing

EOS Electro Optical Systems was founded in 1989 and is the world-wide market leader in the field of laser-sintering. The technology, originally developed as rapid prototyping, has established itself in the areas of plastics and also metals as the key technology for e-Manufacturing. It is increasingly replacing conventional manufacturing processes, in particular for small to medium-sized series and for bespoke and complex products. EOS completed its last business year on 30 September 2006 with a preliminary turnover of more than 50 million EUR and currently employs more than 200 employees worldwide – 180 of these at its headquarters in Krailling near Munich.

Sirona and infiniDent

The company was founded in 1997 from the former dental division of Siemens. Sirona Dental Systems GmbH is the international leading manufacturer of dental equipment. In June 2006 the company took over Schick Technologies, Inc., the radiographic imaging specialist. Since then, Sirona Dental Systems, Inc. has been listed on the NASDAQ, the US exchange for technology stocks. Sirona currently employs around 1,900 employees. The company is essentially setting the technological and economical standards in the dental laboratory industry. Sirona is the ultimate market leader in CAD/CAM systems for the manufacture of ceramic and metal dental prostheses. Since 2004 the company has been offering the technology-based production service infiniDent.