Founded 30 years ago by John Dunn, Swindon Racing Engines’ initial business was to service the Ford DFV Formula 1 engines. Thanks to its quality performance and knowledgeable engineering staff, Swindon Racing Engines was soon developing the next-generation DFV engines as well. The company has steadily built its business upon these strengths and today is known around the world for the superior racing engines it designs and manufactures.

Founded 30 years ago by John Dunn, Swindon Racing Engines’ initial business was to service the Ford DFV Formula 1 engines. Thanks to its quality performance and knowledgeable engineering staff, Swindon Racing Engines was soon developing the next-generation DFV engines as well. The company has steadily built its business upon these strengths and today is known around the world for the superior racing engines it designs and manufactures.

Cars with Swindon engines have won championships in Formula 1, Formula 3000, Formula 3, World Sportscars, British Touring Cars, International Touring Cars and many other classifications. Today, the company continues to thrive with John’s son Gary at the wheel. When he took over in 1996, Gary knew that to maintain Swindon’s reputation as a leader in its field, and to meet the ever increasing design challenges and production requirements of its customers, the company would need to adopt powerful computer design and manufacturing capabilities. While recognizing the need to transform the digital development process with 3D CAD and to eliminate waste in the manufacturing steps with CAM, Gary also required solutions that would be easily implemented and quickly adopted by the users so as not to interrupt the company’s output of product.

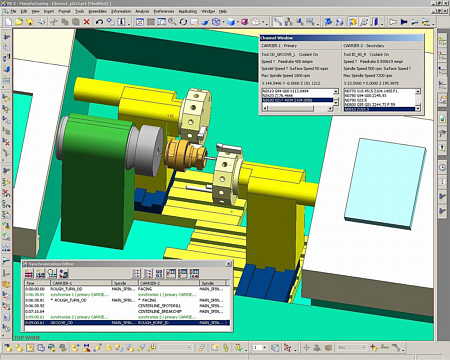

Powerful computing tools yield results from start to finish Swindon selected Solid Edge as the 3D CAD system because of the broad array of functionalities it offers. Using Solid Edge, Swindon designs with insight to create virtual prototypes of every component it manufactures. These 3D models are combined into virtual assemblies, and the team can check for part interferences. “Not only has design time been drastically reduced,” says Gary Dunn. “But changes and development procedures can be achieved efficiently and easily.” When a physical prototype is needed to verify design functionality, the engineers at Swindon can quickly and easily spin off data from the 3D model to create a rapid prototype. The team at Swindon uses the 3D models created in Solid Edge in non-technical applications as well. Digital models are used to keep Swindon’s customers happy by helping them to better understand and visualize engine installations. And, in an effort to support its customers’ marketing needs, Swindon leverages the data from the 3D models to create detailed component images which can be used for presentations to potential team sponsors. Pleased with the results from using Solid Edge, Dunn knew he needed to add a CAM capability to complete the development process transformation. After a thorough review of high-end CAM systems, the company chose NX. “NX had all the functionality of the other systems we reviewed,” says Sean O’Rafferty, production manager at Swindon. “But NX offered more flexibility, meaning more ways to accomplish a certain task, than any of the other software systems.” Since the designers have daily deadlines they must meet to support product development, easy implementation of the new CAM system was important. “There is always a period of adjustment with any new software, but when compared to the others, NX felt intuitive. We were impressed with the way it guides the user around in a logical manner,” O’Rafferty adds. “And the 24-hour-a-day, worldwide customer support offered by UGS is second to none.”

Customer need accelerates realization of huge efficiency gains When Swindon won a contract to modify cylinder heads in very high volumes, the combination of Solid Edge and NX made it possible to dramatically increase production capacity. The customer required 560 cylinder heads per month, yet Swindon’s production rate at the time was only 20 heads a month. By feeding Solid Edge CAD data directly into NX, it is possible to eliminate the often inaccurate and time-consuming manual programming of the 5-axis milling machine. Swindon’s 5-axis machine can begin cutting chips as soon as the design data is received.

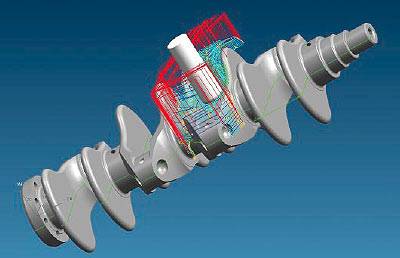

Swindon not only supported its customer’s quantity requirement but also yielded a very impressive 2,800 percent increase in its cylinder head production capacity! And this is true for even very complex designs. “If the designers come up with a complicated design we want to translate into the CAM environment, we’re able to do that now. We haven’t come across a design that we haven’t been able to machine using NX.” One of the many other facets of a Swindon engine that has contributed to its highoctane reputation is the crankshaft it produces using materials commonly found in aerospace products. Here too, Swindon uses Solid Edge and NX to transform the digital development process by eliminating waste.

“The turning package in NX is outstanding,” says Dunn.

“It provides us with several different options for creating grooves which allows us to work faster and eliminate a lot of downtime we previously had in machining these components.”

Capitalizing on its dramatic increase in its production capacity, Swindon is now recognized as the first engine design and manufacturing company to mass-produce cylinder head conversions for the motor sports industry. Adding that accomplishment to its recently announced winning of the contract to manufacture the race car engines for Chevrolet’s entry into the 2005 FIA World Touring Car Championship, it’s easy to see Swindon leading the field for many years to come.

www.swindon-engines.com

www.solidedge.com