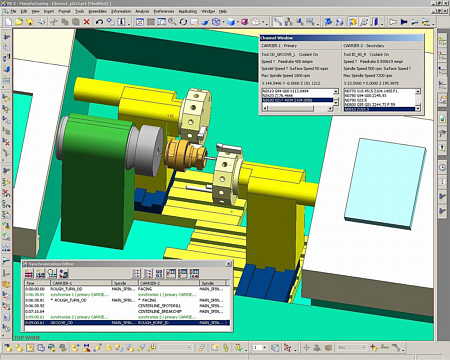

NX CAM from Product Lifecycle Management Australasia (plm) is providing a means for design/manufacture businesses to streamline shop floor operations and actively reduce the number of steps from design to production.

Moreover, the fast growing list of users find NX CAM capabilities mean that far less CAD input – sometimes none at all – is required when the true benefits of CAM are rolled out.

NX CAM fulfils all the requirements of those manufacturers needing a CAM-specific solution. It provides benefits both as an element of a standalone CAD/CAM solution or in a multi-CAD environment where data may come from a variety of CAD sources.

NX CAM also offers an unmatched range of capabilities, yet the automation capabilities such as the process templates and process assistants, make the system easy to use.

These same automation techniques enable preferred processes to be followed for each type of operation or product, which makes the system more productive, and leads to higher quality and consistent results.

The ability to work directly from the features defined in CAD model geometry with a high degree of associativity means that design information can be efficiently utilised directly in the manufacturing process.

Seco Tools

Panel on NX CAM

One plm client, Seco Tools, chose NX CAM in order to remain competitive in one of the more challenging niche sectors of Australia – the cutting tool industry.

This organisation recently commenced training on NX CAM predominantly to move away from a longstanding dependence on CAD software, and thus speed up productivity on the workshop floor.

As the company’s Technical Manager, Dean Townsend explains, Seco Tools took on CAM software as part of a national group standardisation.

“Basically, we were only using CAD software but wanted to unify and use CAM to give us that direct digital step from design to manufacturing, basically bypassing that CAD step.

“Originally, we thought NX CAM may be a difficult program to which we had to adjust, but it is generally quite easy to use, especially after the training we received from plm.

“We were put through a ‘rapid start’ CAM course inclusive of post processing. The ease of use was apparent as early as day three, when the programmer was effortlessly making parts on the machine and in the way he wanted to machine them.

“The digital design environment is crucial to our productivity as the commercial pressure is always on to manufacture special tooling for the cutting industry through a multinational Seco Tools organisation, but we also specialise in specific solutions as they arise.”

Seco Tools now finds its efficiency level with NX CAM is quite high. Over just one daily shift, one user of the CAM software will generally speed up jobs. It is the software’s high level of visualisation that provides a critical element during the design phase.

Essentially, with this bypassing of what was formerly the company’s CAD process it is able to make sure there are no ‘collisions’ on the production line before jobs actually go onto the machine.

For many companies, the ability to centralise control is a huge asset on their production line. With the high level of automation now responsible for making almost everything we use in society, a major aim of manufacturing managers is to remain on top of what is happening on the factory floor. B&S Engineering

plm client B&S Engineering specialises in precision tooling for making caps and tamper evident closures such as hinged and unscrewing bottle tops.

The company doesn’t mould them, it builds the tools that manufacture these plastic parts. Often these are quite large intricate jobs.

B&S wanted a greater level of streamlining and turned to the NX CAM package.

The company’s main CAD operator Brian Maher says that prior to the introduction of NX CAM, the CAD room was performing everything, including modelling, drafting, and cutter paths.

“But now, we link a file through the main assembly, to the shop floor where cutter paths are produced,” said Mr Maher.

“We gain a much greater simplified control over the entire job with NX CAM and the staff on the shop floor cannot inadvertently make model changes. Updates in the CAD room are automatically linked to the shop floor, because all out data is in one place.”

NX CAM has the ability to work directly from the features defined in CAD model geometry with a high degree of associativity which means that all design information can be efficiently utilised directly in the manufacturing process.

It fulfils all the requirements of those manufacturers needing a CAM-specific solution. NX CAM provides benefits both as an element of a standalone CAD/CAM solution or in a multi-CAD environment where data may come from a variety of CAD sources.

“NX CAM offers us an unmatched range of capabilities, yet the automation capabilities such as the process templates and process assistants, make the system easy to use and versatile.” Said Mr Maher.

“This technique enables the process system to be more productive, and leads to higher quality output and consistent results.

“NX CAM is proving to be efficient in our application. We are considering installing NX CAM next to our other Mazak machining centres and our Sodick 4-axis wire-cutter in the future”

Product Lifecycle Management Australasia

That makes life easier

this is a observant piece of technology very interesting i realy like the pictures so so cool.