When approached to construct a custom-built 98′ yacht designed by Fontaine Design Group, Michael McClain of Hodgdon Yachts, East Boothbay, Maine, relied on ALGOR FEA software to optimize existing vessel designs to save time, ensure safety, reduce hull weight and save money.

When approached to construct a custom-built 98′ yacht designed by Fontaine Design Group, Michael McClain of Hodgdon Yachts, East Boothbay, Maine, relied on ALGOR FEA software to optimize existing vessel designs to save time, ensure safety, reduce hull weight and save money.

Hodgdon, a premier builder of sea vessels since 1816, had previously relied exclusively on empirical observation, hand analysis, a handbook of shipping standards and classical techniques for its hull designs. However, McClain had used FEA software for over three years before assuming his current position as the Composite Production Engineer at Hodgdon and knew that FEA software could save design and testing time. After reviewing several other software packages, Hodgdon Yachts chose ALGOR based on value for the investment, performance and user comfort with the software. Cold-Molded Design

Hodgdon’s custom superyachts are constructed using a state-of-the-art, cold-molded wood epoxy technique that produces their trademark custom hulls. In cold-molded design, the hull is built up in layers consisting of thin wood strips over fine layers of epoxy. Each layer is vacuum-bagged, eliminating voids and creating a homogeneous structure. The hull is then covered by fiberglass plies, set in epoxy and post-cured to 140 degrees F, resulting in a non-corrosive, blister-free surface. Depending on the size of the craft and the level of finish, the entire custom construction can take anywhere from 12 to 48 months and dozens of skilled craftsmen.

Several design considerations led Hodgdon to use FEA, including the need to save time during construction. Each layer in the cold-molded process adds significant time to the construction process. So a reduction in the number of plies would mean a shorter time to market. Other design goals included optimizing materials, thus cutting costs, while creating a stronger vessel. An additional design goal was to reduce the weight of the 98′ yacht.

Several design considerations led Hodgdon to use FEA, including the need to save time during construction. Each layer in the cold-molded process adds significant time to the construction process. So a reduction in the number of plies would mean a shorter time to market. Other design goals included optimizing materials, thus cutting costs, while creating a stronger vessel. An additional design goal was to reduce the weight of the 98′ yacht.

The design was completed jointly by Fontaine Design of Rhode Island and Hodgdon’s own six-person design crew. McClain proceeded to model the areas of the ship that were subject to high stresses. His aim was to employ an engineered approach to the design based on physics, in order to make a lighter, yet safe vessel. ALGOR and Hodgdon: Advanced Technology and World-Renown Craftsmanship

Using Rhinoceros to model some of the parts, McClain imported the drawings directly into ALGOR. He then generated additional elements using the Wood Handbook of the American Bureau of Shipping Standards and test data supplied by Dr. Robert F. Lindyberg of the University of Maine’s Advanced Engineered Wood Composites Center (AEWC).

Three areas were at issue: the portholes, the forepeak and the chain plates. McClain’s first area of concern was the hull structure in the Owner’s Stateroom. He wanted to examine this area in order to determine the effect of two portholes within the same span between frames.

Of concern was the strength of the area around the two portholes. McClain used a wide range of meshing refinements, from coarse meshing in most areas, to fine meshing at points of interest. The model of the area was then subjected, one layer at a time, to linear static stress tests, checking for the effects of forces on the structural features. Materials and applied loads were determined using the American Bureau of Shipping Standards criteria for known forces on sea vessels, as well as data supplied by the University of Maine AEWC. McClain checked the von Mises stress results to ensure that the composites were well within yield standards.

Of concern was the strength of the area around the two portholes. McClain used a wide range of meshing refinements, from coarse meshing in most areas, to fine meshing at points of interest. The model of the area was then subjected, one layer at a time, to linear static stress tests, checking for the effects of forces on the structural features. Materials and applied loads were determined using the American Bureau of Shipping Standards criteria for known forces on sea vessels, as well as data supplied by the University of Maine AEWC. McClain checked the von Mises stress results to ensure that the composites were well within yield standards.

The results of the analysis on this area of the hull indicated a need to strengthen the structure around the portholes. McClain experimented with different woods and the numbers of plies, given his primary goal of eliminating material and reducing weight, if possible. Based on his analysis, he was able to reduce the number of plies by substituting the stronger Douglas fir in place of the standard Western Red Cedar used throughout most of the vessel. At the same time, he strengthened the area. This reduction in plies represented a weight savings of hundreds of pounds. With this change alone, Hodgdon was able to cut costs, time and hull weight, while also making a stronger vessel.

Hodgdon designers also looked at both the main and mizzenmast chain plates. The chain plates are reaction points for the loads from the rigging and mast. Chain plates are typically mounted on the hull. Again, McClain looked for stress points and compared those to yield standards. Based on four or five iterations of the plates from ALGOR analyses, the plates were reduced in weight and moved from the hull to bulkheads. Hodgdon saved more time and further reduced hull weight by eliminating the need to build up the hull for plate attachment. The analyses and subsequent iterations in the ALGOR FEA software allowed McClain to add lightening holes, put in buckle plates and change thicknesses to minimize weight, while staying within yield standards. “We used ALGOR to examine the loads and stresses in both the chain plate and the bulkhead to determine if moving the chain plate to the bulkhead was feasible, which it turned out to be,” McClain said.

Overall, the use of ALGOR FEA resulted in an improved design for the award-winning yacht builder. “Our skilled craftsmanship partnered with ALGOR’s advanced technology resulted in a superior new yacht design,” said McClain. Hodgdon and ALGOR FEA: Future Plans

Overall, the use of ALGOR FEA resulted in an improved design for the award-winning yacht builder. “Our skilled craftsmanship partnered with ALGOR’s advanced technology resulted in a superior new yacht design,” said McClain. Hodgdon and ALGOR FEA: Future Plans

Given the success in using ALGOR FEA on the 98′ yacht, McClain plans to use the software in the design process of subsequent recreational vessels.

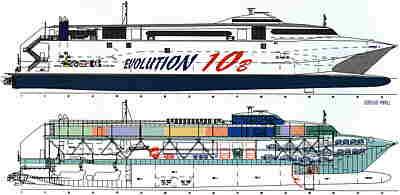

In addition to its use of ALGOR for recreational vessels, Hodgdon is also using the software for the design of crafts used by U.S. Military Special Operations Forces. In partnership with the University of Maine AEWC, Donald Blount & Associates, Inc. and Eric Green Associates, Hodgdon secured a one million dollar Federal contract in 2004 to design a prototype for a high-speed composite hull for a U.S. Navy medium range insertion craft (MRIC). The craft will be used to deliver Special Operations Forces in a safe, stealthy and secure manner. Design criteria include improved range, high speed and most importantly, improved sea-keeping. “We will use ALGOR in conjunction with the experimental test results to produce a world-class vessel that continues the proud legacy of excellence for which the SEALs and Hodgdon Yachts are known,” said McClain.

Hodgdon Yachts Michael McClain holds Bachelor’s and Master’s degrees in Engineering from Virginia Tech. He worked at Lockheed Martin Manned Space Systems and the Bath Iron Works Advanced Technology Division before assuming his position at Hodgdon Yachts.

Hodgdon Yachts Michael McClain holds Bachelor’s and Master’s degrees in Engineering from Virginia Tech. He worked at Lockheed Martin Manned Space Systems and the Bath Iron Works Advanced Technology Division before assuming his position at Hodgdon Yachts.