Mirajker Design used Mechanical Desktop to design the components for the Aquajack control unit with solid and surface modeling.

Mirajker Design has designed a domestic water pump intended for residential buildings in India and other countries which currently use manual pumps and other techniques for transferring water to overhead tanks. The new pump, named the Aquajack, automatically monitors water levels and controls its own operation resulting in more reliable water supply and higher energy efficiency.

Mirajker Design, an industrial design and engineering firm based in Madras, India, specializes in transportation design. Its clients include Tata Engineering and Locomotive Company, Hindustan Motors Limited, and Punjab Tractors, to name a few. For its efforts, the company has won international car design competitions. The company also designs consumer products, and its services range from concept through full-scale models and prototypes.

Since the municipal water supply in most Indian cities is erratic, residents use water pumps to bring sump or well water into water storage tanks located in nearly every building. The usual way to operate the water pump is to manually switch the pump motor on and off. This manual operation is inconvenient and can result in damage to the equipment.

Mirajker Design used Mechanical Desktop to design the Aquajack control unit for Sharp Tools, based in Coimbatore, India. The control unit monitors the water levels in the sump and water tank, and switches a water pump automatically. By sensing the fluid levels and controlling the motor accordingly, Aquajack also reduces electricity and water waste. Moreover, Aquajack warns of dry sump runs that can damage the pump and motor, and also recognizes fluctuations in the electricity supply, automatically shutting off to prevent damage to the equipment. The pump is also self diagnostic. It indicates system failures, and includes an override option so the pump can be controlled manually until the faulty components can be serviced.

“The value of Mechanical Desktop is that I am able to fully visualize my designs, and eliminate problems that could occur during production,” Rajesh Mirajker says. “Also, assembling the model on screen enables me to identify fit problems and validate layouts. I also find the surface modeling powerful. And, the fact that my model maker and I can see the results before the pattern or model is made saves time and reduces prototyping costs.”

“On this project alone, we’ve reduced the pattern making process by about 50 percent and prototyping costs by about 25 percent,” says Mirajker. “There was no wastage of material and no reiterations or reworks on detail shapes. These were very clearly depicted on my surface draft drawings and 3D model views. Communication with my model maker was also much easier — most times I did not have to be present on the shop floor,” he says.

According to Mirajker, the client is happy with the designs. Aquajack is slated for manufacture in Coimbatore, India. Mirajker believes this product will sell quite well. “In India it is sure to sell in most cities where the water supply is not consistent,” Mirajker comments. Aquajack frees residents from everyday water management chores, reduces water and electricity waste, prevents equipment damage and the control panel is visually appealing.

Inside a building, the Aquajack works as an automated domestic water pump system to manage the transfer of water in buildings from a sump to the overhead tank. The system senses water levels, preventing overflows. It also conserves electricity and eliminates daily attention by the building residents.

The Aquajack water pump monitors the water levels in the sump and water tank, and pumps automatically. By sensing the fluid levels and controlling the motor accordingly, Aquajack also reduces electricity and water waste. Moreover, Aquajack warns of dry sump runs that can damage the pump and motor, and also recognizes fluctuations in the electricity supply, automatically shutting off to prevent damage to the equipment. The pump is also self diagnostic. It indicates system failures, and includes an override option so the pump can be controlled manually until the faulty components can be serviced.

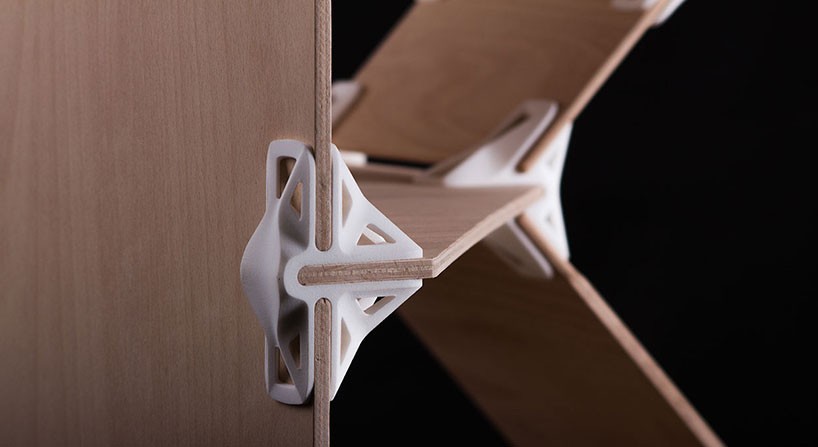

Aquajack control unit with bottom cover removed.

The Aquajack control unit is mounted indoors where residents can monitor the process if necessary. The only ‘up-front’ device, the switchgear appears attractive and adds value in terms of sophistication to the whole system. The control unit is wired to the electric motor pump (housed separately near the sump tank), and is connected to sensors in the sump and overhead tanks, and other sensors appropriately positioned on the water plumbing. The need to inspect the motor-pump, water tanks and plumbing on an every-day basis becomes unnecessary since the control unit continuously displays activity status of the entire system, and warns of failures.

The Aquajack control unit switches on and shuts off the electric motor pump automatically, based on inputs from the sensor switches located in the sump and overhead tanks. There are also other sensors to indicate air-locks in the plumbing at the motor pump, and a proprietary electronic system regulates the motor for the load deficiencies caused by the air trapped in the plumbing. The control unit also has self diagnostic features to monitor power supply fluctuations and system failures. Aquajack shuts down automatic operation in such cases, and allows a manual override option, enabling operation of the motor pump selectively, until the necessary repairs are made.

Manual sketches of different ideas initiated details for alternative styling proposals. The selected style was then manually drafted as a layout space claim, where overall details were sorted. Individual parts were then modeled with AutoCAD, starting first with the chassis, and then referencing all other mating parts to this base. Parts were next created independently as surface models, and parametric solid models, with Mechanical

Desktop. These models were also supported by orthographic design and pattern drawings. These drawings were then manually assembled by external referencing to create a composite assembly of solid and surface models. The composite model was subsequently used for re-checking the layout and parts fit on the product, resulting finally in an exploded assembly drawing including the bill of material. Plots of the ortho drawings were referred for the prototype fabrication.

Mechanical Desktop enables Mirajker Design to customize design solutions for individual clients. In addition to reducing prototyping costs, Mechanical Desktop makes it easier to identify fit problems and validate layouts, improve communication with the model maker and client, and increase efficiency with its use of parametric modeling.