College and university teams from around the world competed in the SAE Collegiate Design Series Formula SAE® Competition from May 15 to 19, 2002, at the Pontiac Silverdome in Pontiac, Michigan. Each team had designed and built an entire racecar during the school year, and these cars were judged in categories including cost, presentation, design and acceleration. A successful performance in the competition shows that students can effectively put the concepts they are learning in the classroom into practice using real-world engineering tools to produce a cost-effective and functional product. This year’s Saginaw Valley State University Formula SAE team placed sixth overall among 125 teams, using Solid Edge computer-aided design (CAD) and ALGOR finite element analysis (FEA) software for computer-based modeling and analysis of its racecar. The FEA software used was granted to the team as part of ALGOR’s ongoing program to support academic engineering competitions.

College and university teams from around the world competed in the SAE Collegiate Design Series Formula SAE® Competition from May 15 to 19, 2002, at the Pontiac Silverdome in Pontiac, Michigan. Each team had designed and built an entire racecar during the school year, and these cars were judged in categories including cost, presentation, design and acceleration. A successful performance in the competition shows that students can effectively put the concepts they are learning in the classroom into practice using real-world engineering tools to produce a cost-effective and functional product. This year’s Saginaw Valley State University Formula SAE team placed sixth overall among 125 teams, using Solid Edge computer-aided design (CAD) and ALGOR finite element analysis (FEA) software for computer-based modeling and analysis of its racecar. The FEA software used was granted to the team as part of ALGOR’s ongoing program to support academic engineering competitions.

Every member of the Saginaw Valley State University Formula SAE team was involved in designing and building the 2002 racecar. The members wanted to get Windows® 98 based software they could all use on the team’s bank of computers to access files, make modifications and run analyses. After researching available options, the team requested and received an ALGOR grant for FEA software that they had learned about from another Formula SAE competitor, and Faculty Advisor Dr. Brooks Byam obtained an educational license for the Solid Edge CAD software. ALGOR’s FEA software integrates seamlessly with Solid Edge, working with the exact CAD geometry to eliminate the need for data translation and providing associativity for each design change.

Linear static stress analysis performed on this Solid Edge model of the rear upright of Saginaw Valley State University’s 2002 Formula SAE racecar An ALGOR linear static stress analysis performed on this Solid Edge model of the rear upright of Saginaw Valley State University’s 2002 Formula SAE racecar yielded satisfactory results, enabling the team to immediately begin building the part. (Model courtesy of Dr. Brooks Byam, Saginaw Valley State University Formula SAE team.)

The team followed a tight production schedule because Formula SAE now requires that all cars be built from scratch each year, whereas teams prior to 2002 were permitted to use the same car for two years. Chief Engineer George Coppens said, “We were able to design and build the entire car within nine months.” One way in which the team controlled its time investment was by performing FEA to verify designs of only the parts that would experience the most stress and were therefore most likely to fail: the rockers or bell cranks, the rear uprights and especially the front uprights. “The front uprights are right inside the wheels, so they see the greatest loads of any car part and it is essential that they not break,” Coppens said.

The team followed a tight production schedule because Formula SAE now requires that all cars be built from scratch each year, whereas teams prior to 2002 were permitted to use the same car for two years. Chief Engineer George Coppens said, “We were able to design and build the entire car within nine months.” One way in which the team controlled its time investment was by performing FEA to verify designs of only the parts that would experience the most stress and were therefore most likely to fail: the rockers or bell cranks, the rear uprights and especially the front uprights. “The front uprights are right inside the wheels, so they see the greatest loads of any car part and it is essential that they not break,” Coppens said.

Loads to represent the maximum and steady-state weight transfer were calculated after mounting accelerometers on the 2001 car and running it. The entire weight of the car was applied to the front uprights to simulate stress on the front corners when turning. Coppens said all loads were estimated high to simulate “worst-case” scenarios when racing.

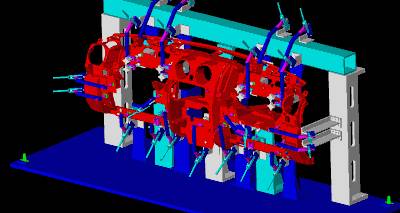

Saginaw Valley State University Formula SAE team’s 2002 racecar The Saginaw Valley State University Formula SAE team’s 2002 racecar, which earned sixth place in the annual competition at the Pontiac Silverdome, included uprights (top left) and rockers (top right) in the suspension (rear shown in center) that were built after Solid Edge designs were satisfactorily validated using static stress analysis in ALGOR. . (Photograph courtesy of Dr. Brooks Byam, Saginaw Valley State University Formula SAE team.)

Once load values were established and applied, team members performed linear static stress analysis on the front and rear uprights and the front and rear rockers. “When ALGOR FEA showed parts wouldn’t fail, we immediately built them,” Coppens said. Analysis simulates real-world events, so the team could tell by using the CAD and FEA tools – without wasting time and materials for each part’s testing – that designs would hold up under estimated loads. In this way, the team completed a prototype racecar a few weeks ahead of schedule and was able to test its real-world performance and make modifications to it as appropriate.

Once load values were established and applied, team members performed linear static stress analysis on the front and rear uprights and the front and rear rockers. “When ALGOR FEA showed parts wouldn’t fail, we immediately built them,” Coppens said. Analysis simulates real-world events, so the team could tell by using the CAD and FEA tools – without wasting time and materials for each part’s testing – that designs would hold up under estimated loads. In this way, the team completed a prototype racecar a few weeks ahead of schedule and was able to test its real-world performance and make modifications to it as appropriate.

Regarding the advantages of participating in Formula SAE, Coppens said it provides the best way to get practical experience for university students, including the opportunity to use real-world engineering tools like Solid Edge and ALGOR software. He said, “It’s a huge engineering project – you’re building a whole car, and you’re learning how engineers really do that and using the same tools.”

After this year’s improvement to a sixth place finish from 51st in 2001, the Saginaw Valley State University Formula SAE Team hopes to continue its climb toward first place in 2003.

SAE Collegiate Design Series Formula SAE® Competition

Saginaw Valley State University

Solid Edge

Algor