Top-of-the-line design technology is commonplace around the facilities of Formula 1 and NASCAR teams, those enviable organizations with lots of sponsors and plenty of money. But in the garages of smaller teams, such as those around Indianapolis, in the shadow of the city’s famed motor speedway, CAD, CAM and CAE are still pretty unusual. Jeff Berger, director of an Indianapolis-based engineering firm called Fin-el (Indianapolis, Indiana), recently teamed up with race car manufacturer, FABCAR, on a project that may change all that. “I hope our success with the Grand Am Daytona Prototype will help convince smaller teams that this technology can be useful to them, too,” Berger says.

Top-of-the-line design technology is commonplace around the facilities of Formula 1 and NASCAR teams, those enviable organizations with lots of sponsors and plenty of money. But in the garages of smaller teams, such as those around Indianapolis, in the shadow of the city’s famed motor speedway, CAD, CAM and CAE are still pretty unusual. Jeff Berger, director of an Indianapolis-based engineering firm called Fin-el (Indianapolis, Indiana), recently teamed up with race car manufacturer, FABCAR, on a project that may change all that. “I hope our success with the Grand Am Daytona Prototype will help convince smaller teams that this technology can be useful to them, too,” Berger says.

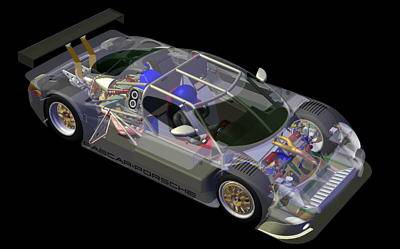

The Daytona Prototype is a new class of Grand Am racing car scheduled to debut in the 2003 season of the Rolex Sports Car Series, the series that sponsors the Rolex 24 At Daytona and other endurance races. Berger assisted Carmel, Indiana-based FABCAR, one of sport’s top car builders, in developing the Daytona Prototype. What’s unusual about this project is that the entire vehicle, including composite body surfaces, was modeled in Solid Edge by auto racing veterans who wouldn’t normally turn to high tech. On March 1, the Brumos Racing #59 FABCAR scored its maiden win in the Nextel Grand Prix of Miami at Homestead-Miami Speedway. Veteran driver Hurley Haywood and rookie J.C. France piloted the victory in the 250-mile Rolex Sports Car Series race.

Parametrics simplify surface changes

FABCAR got involved in the project when Grand Am was still deciding on what type of car it wanted. The organization had determined that the new car would have a closed cockpit “to make it look more like a regular car that fans could identify with,” Berger says. But it wanted input from manufacturers such as FABCAR about the rest of the car’s appearance. FABCAR had recently purchased Solid Edge, an EDS PLM Solutions product, from Berger’s company, Fin-el, and asked him to assist with the work for Grand Am.

Berger mocked up several body alternatives in Solid Edge. “It wasn’t like I just sat down and whipped out a car,” he explains. “I’d spent weeks beforehand setting up the workflow. Once I had that, I could come up with variations of the car body in just a day or two.” Berger used the software’s rendering capabilities to create realistic images of his designs. These were sent to Grand Am to help officials there visualize his work and later, to the series’ other car manufacturers to promote the new concept.

Once Grand Am had settled on the overall look of the car, FABCAR asked Fin-el to stay on and help make the new concept a reality. While engineers from both FABCAR and Fin-el worked on the mechanical design Berger concentrated on the body. Everyone shared Solid Edge files electronically to coordinate their efforts. During this time a key advantage of modeling body surfaces in Solid Edge became apparent. “As we were designing the car, Grand Am was still evolving the rules,” Berger says.

“If we’d been working with drawings, or even a traditional surfacing program, it would have been difficult to evolve the design as the rules changed. With drawings, it would have meant starting from scratch. In surfacing software, it would have involved modifying each surface and reattaching it to the surrounding surfaces. With Solid Edge’s parametric modeling capabilities, we could just type in a change to the underlying sketch and all affected surfaces were automatically updated.”

Many uses for models

Berger exported body models in .stl format to a rapid prototyping facility that made a one-eighteenth scale model of the car. He performed computational fluid dynamics (CFD) analysis on some body components to fine-tune their aerodynamics, and more CFD worked is planned for the future. Berger imported files of the suspension and roll bar from FABCAR into the finite-element analysis program, CAEFEM (a Solid Edge Voyager Program from Concurrent Analysis Corporation), to test the functionality of these parts before they were built. And when it came time to build the car, Solid Edge files were used in the CAM program, Virtual Gibbs (from Voyager Program member Gibbs and Associates), as the basis for machining instructions.

How did the new car turn out?

How did the new car turn out? Three have been sold. One was purchased by Brumos Racing, whose crew and drivers celebrated the March 2003 victory at the Nextel Grand Prix of Miami. They also had celebrated in the pits of Daytona International Speedway on Dec. 7, 2002 after the Porsche- powered vehicle crossed the finish line to conclude a hugely successful 28-hour test run.

“The Brumos Racing Daytona Prototype performed close to flawless throughout the entire weekend of testing,” proclaims the Grand Am web site. The second car set the fastest time in pre-race qualifying. The third is also a competitive force and running trouble-free.

“It’s a real testament to Dave Klym and FABCAR,” said David Donohue, one of the eight drivers who piloted the car during the 28 hours. People behind the scenes of the car’s development knew that its flawless performance was a testament to Solid Edge and Fin-el as well. If Berger’s mission is as successful as the first Solid Edge-designed race car, he is going to change the way things are done around Indianapolis.

Fin-el provides engineering and design services as well as sales and support of engineering software. Services include product development, component design optimization, and virtual prototyping through 3D computer modeling, kinematic simulation, finite-element analysis, and computational fluid dynamic analysis.