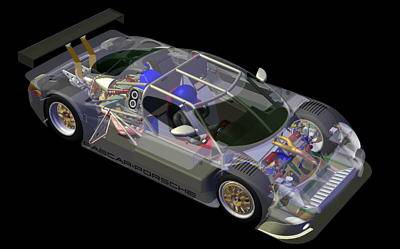

Brothers Ross and Jim Stone, race Ford V8s in the hotly contested saloon car competition in Australia. At first glance these cars appear very similar to the production models on which they are based, albeit lowered, with fat tyres and with the usual frenzy of a sponsorship paintjob. In fact, there is very little of the original production model left in the car that ultimately scorches its way around the racetrack. Although modifications are tightly constrained and rigorously enforced by the racing codes governing each particular competition, there is still plenty of room for engineering creativity at every level. Each of the Stone brothers’ cars embodies a wealth of innovative design, quality manufacturing and the latest and best of appropriate technologies.

Brothers Ross and Jim Stone, race Ford V8s in the hotly contested saloon car competition in Australia. At first glance these cars appear very similar to the production models on which they are based, albeit lowered, with fat tyres and with the usual frenzy of a sponsorship paintjob. In fact, there is very little of the original production model left in the car that ultimately scorches its way around the racetrack. Although modifications are tightly constrained and rigorously enforced by the racing codes governing each particular competition, there is still plenty of room for engineering creativity at every level. Each of the Stone brothers’ cars embodies a wealth of innovative design, quality manufacturing and the latest and best of appropriate technologies.

Headquartered at Yatala in Queensland just north of the famous Surfer’s Paradise, the Stone brothers have been running their own racing team since 1996. Both Ross and Jim have long and illustrious careers in Australian motorsport as a team manager and engineer respectively. Together they brought a wealth of experience when they finally formed their own racing team. SBR employs 27 people and most are engaged in hand-building the team’s three racing cars.

Stone Brothers Racing (SBR) maintains two cars in competition and both are virtually identical although each has a different major sponsor. The cars are based on production sedans as delivered by Ford Australia. Once SBR starts work on them however, these cars leave the world of normal motoring far behind. The main body modifications are completed in around 1000 hours of reworking. Many body components are removed simply to reduce weight. Some are replaced with redesigned components and some that were never there in the first place, like the rollcage, are fitted. While the body is extensive reworked, all modifications must comply with the strict racing code rules.

Mechanical Components

The body is the only part of the racing car that retains any part of the original production car. All the mechanical components are replaced with high-performance gear, better able to take the punishment of racing, and hopefully to add a performance edge over the competition. Some major components are sourced more-or-less ready-to-race. For example racing engines are shipped in from the USA. The gearboxes and differentials are designed and manufactured by leading Australian racing equipment manufacturers.

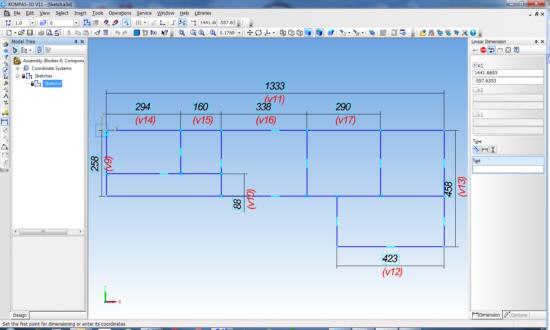

Other components such as the suspension, steering, fuel control and electronics systems are custom designed and made by SBR. SBR engineers use Pro/E software by PTC extensively for mechanical part and assembly design. Complementary PTC software is also used for stress analysis of mechanical parts and structural components as well as motion analysis. GibbsCAM is used prior to CNC machining. SBR does not have any CNC equipment installed in its own machine rooms.

Other components such as the suspension, steering, fuel control and electronics systems are custom designed and made by SBR. SBR engineers use Pro/E software by PTC extensively for mechanical part and assembly design. Complementary PTC software is also used for stress analysis of mechanical parts and structural components as well as motion analysis. GibbsCAM is used prior to CNC machining. SBR does not have any CNC equipment installed in its own machine rooms.

Electronic systems

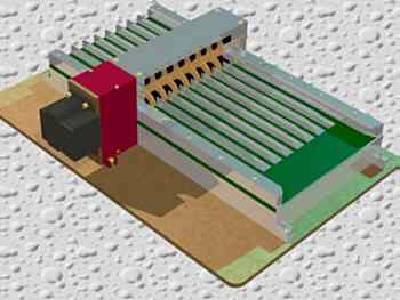

The main data system in the car monitors conditions at numerous points in and around the car. A 3D-accelerometer tracks the motion of the car and 118 channels of data is fed back by radio to a central data control station set up in one of the team’s 18-wheel transport rigs parked beyond the pits. Radio frequencies are allocated by race organizers and provide both data and voice communication channels between car and base. There, engineers can monitor all aspects of the cars racing and mechanical performance. The software used in the control center is a hybrid combination of the commercial vehicle data logging system and proprietary systems software developed by SBR engineers.

Constant, intense monitoring of the car during a race enables problems to be detected even before they occur. This sometimes allows remedial action to be taken during a pitstop and is always used in refining component design and manufacture in readiness for the next race. Overlaying laps can also compare performance data, which highlights consistencies and exceptions over essentially the same ground. This comparison enables drivers to hone their driving techniques for a particular track very quickly. Traditionally such a learning curve would require many more hours of driving and experience, a luxury that is not always available these days.

Constant, intense monitoring of the car during a race enables problems to be detected even before they occur. This sometimes allows remedial action to be taken during a pitstop and is always used in refining component design and manufacture in readiness for the next race. Overlaying laps can also compare performance data, which highlights consistencies and exceptions over essentially the same ground. This comparison enables drivers to hone their driving techniques for a particular track very quickly. Traditionally such a learning curve would require many more hours of driving and experience, a luxury that is not always available these days.

Green Racing

While competitive motor racing in 2002 definitely requires every high tech advantage that can be found, racing codes, sponsors and SBR also see a positive advantage in conducting their activities in an environmentally responsible way. SBR is a “green” motor racing team, which means that it meets responsible sound emission levels (95dbA @ 30m); uses unleaded fuel and environmentally sound pit procedures. There is also a recycling program for all materials used including oil, tyres, discarded brake parts, seals, filters and so on.

SBR has a high tech edge in motor racing and has created a fine team with three very quick cars. Although they are up against some tough contenders in the Australian V8 motorsport competition, they are going all out to make 2002 a big year to remember.

Since this story was published Stone Brothers Racing has merged with Erebus Motorsport V8.