Italian car manufacturer Ferrari leads the field in producing some of the world’s most stylish and powerful sports cars available. In 1952 the company started working with Pininfarina Group, one of Europe’s leaders in the design development and manufacture of high quality cars, and renowned for its automotive development achievements since the 1930s.

Italian car manufacturer Ferrari leads the field in producing some of the world’s most stylish and powerful sports cars available. In 1952 the company started working with Pininfarina Group, one of Europe’s leaders in the design development and manufacture of high quality cars, and renowned for its automotive development achievements since the 1930s.

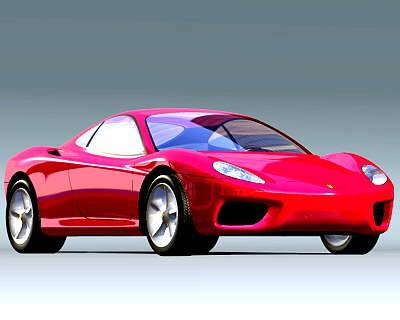

The Ferrari Modena 360, first launched at the Geneva Motor Show in 1999, is the 163rd Ferrari that Pininfarina has designed, adding to an already impressive stable of superbly styled cars that include the legendary Dino, Testarossa and Mythos.

New jewel in the Pininfarina crown

The 295 km/h Ferrari Modena 360 is a thoroughbred from a Ferrari bloodline of some of the world’s finest high performance vehicles. It is the first Ferrari car project to make extensive use of computers not only in the detailing of its main engineering specifications but also in the subsequent development of its styling.

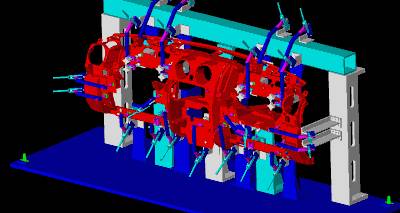

This design project was relatively smooth from the start as it followed a standard procedure that the team at Pininfarina has honed over the years. Initial technical drawings were produced by the Engineering Division, then the Styling and Modeling departments developed and modeled the virtual surface concepts producing virtual models.

Fundamental to the creation of the Ferrari Modena 360 was Alias|Wavefront’s AutoStudio software according to Giuseppe Randazzo, designer and director of the Styling Division within Pininfarina’s Research and Development: “We’ve been using Alias|Wavefront software since 1991 and, from the outset, were enthusiastic about the natural way it allows us to create a three-dimensional model from scratch. We now rely on three AutoStudio licenses. With AutoStudio, initial ideas and concepts can be modeled digitally thanks to the flexible tools built into the software and, as the concept gradually takes shape and its details are refined, we are able to display onscreen a highly realistic model without necessarily having to go to the expense of producing a physical prototype.”

Fundamental to the creation of the Ferrari Modena 360 was Alias|Wavefront’s AutoStudio software according to Giuseppe Randazzo, designer and director of the Styling Division within Pininfarina’s Research and Development: “We’ve been using Alias|Wavefront software since 1991 and, from the outset, were enthusiastic about the natural way it allows us to create a three-dimensional model from scratch. We now rely on three AutoStudio licenses. With AutoStudio, initial ideas and concepts can be modeled digitally thanks to the flexible tools built into the software and, as the concept gradually takes shape and its details are refined, we are able to display onscreen a highly realistic model without necessarily having to go to the expense of producing a physical prototype.”

Virtual models speed throughput

AutoStudio enabled Randazzo and his team to model and display the Ferrari Modena 360 from every side and from different perspectives in real time as well as monitoring the progress of the design project at every stage. This allowed for immediate visualization of any changes and ensured total convergence between the initial concept and the creation of the final product.

Besides the ease and speed with which modifications could be displayed, AutoStudio also contributed to a reduction in product development costs, thereby increasing productivity, according to Randazzo. The software delivers perfect visualization of the computer-generated models and these have now reached such levels of photo-realism that they make the photograph of a real object virtually indistinguishable from a rendered image. “The adoption of AutoStudio has simplified the workflow and to an extent has revolutionized our working practices. Initially the Style Center was able to produce only sketches and physical models, which were then sent to the Design department. Alias|Wavefront software and the introduction of mathematically-accurate models have allowed us to reduce lead times and to create a product whose production was tracked and verified at every step,” he said.

All this has profoundly altered the way Randazzo’s team thinks about how work is done; it has allowed the group to “parallelize” projects and to implement interaction between the different divisions within the Pininfarina Group, which can now monitor and modify throughout the design process with ease. Racing to the future

All this has profoundly altered the way Randazzo’s team thinks about how work is done; it has allowed the group to “parallelize” projects and to implement interaction between the different divisions within the Pininfarina Group, which can now monitor and modify throughout the design process with ease. Racing to the future

The Ferrari Modena 360 is characterized by a fluid and organic design, and therefore it is made up of complex and interlinking surfaces. Despite the design complexity, the process of defining the design mathematics was fairly straightforward even though complex models such as these require continuous feedback against engineering criteria to ensure they match technical specifications.

“Engineering provides us with increasingly detailed technical input requiring more powerful and accurate technology to achieve the right result. Better technology has had a positive effect on lead times and the quality of the items produced. The development cycle of the Ferrari Modena 360 is proof of the contribution that technology has made to the automotive design process,” asserted Randazzo.

Commenting on the future, Randazzo said he and his team are looking to test the potential of Alias|Wavefront’s AutoStudio by using it to design not only the exterior of cars but also styling interiors, and as a tool for the full model modification and finalization stages.

“We can then use these digital models to verify our work through visualization techniques such as virtual reality. Our goal is to drastically reduce the number of physical prototypes. This is the future we have in mind.”

About Pininfarina

The company was founded in 1930 by Battista Pininfarina, who set out to build a coachwork company that devoted itself to the design of highly crafted car body styling for individual customers and for limited run production.

In the 1950s and 60s, Pininfarina’s customers included some of the leading names in the automobile world including Nash, Peugeot, Ferrari, Fiat and Alfa Romeo. In the late 1960s a separate Studies and Research Center was established which benefited from Pininfarina’s investment in automation and computing and put the company at the forefront of automated car body design and styling.

In 1981 the Studies and Research Center became an independent company, Pininfarina Studi e Ricerche, with an unrivalled automotive client base. Today the Industrie Pininfarina Group now encompasses automotive design, component design and production all the way up to the assembly of complete vehicles. The company is looking beyond the traditional automotive sector with diversification into marine design and other transport solutions.

In 1981 the Studies and Research Center became an independent company, Pininfarina Studi e Ricerche, with an unrivalled automotive client base. Today the Industrie Pininfarina Group now encompasses automotive design, component design and production all the way up to the assembly of complete vehicles. The company is looking beyond the traditional automotive sector with diversification into marine design and other transport solutions.

With a workforce of over 2,500 and sales of Euro 683 million, the group has established itself as a competitive industrial force, which has grown successfully by keeping alive and valuing not only its roots, but also the cultivation of product and attention to its formal, technological and constructional quality.