Split-Cycle Technology Limited is a Research and Development company located on Australia’s Gold Coast. The company’s technology represents a revolutionary break-through in internal combustion engine design.

Split-Cycle Technology Limited is a Research and Development company located on Australia’s Gold Coast. The company’s technology represents a revolutionary break-through in internal combustion engine design.

Split-Cycle Technology’s three areas of research are:

- The Split-Cycle Engine: The engine is being developed as an alternative to the conventional piston-conrod-crankshaft configuration of the internal combustion engine. Using a unique combination of geneva wheels and compression ratios as low as 1.4 to 1, the Split-Cycle Technology engine delivers high torque values with far greater economy and less environmental impact.

- The Pulse Fuel Injector: The Pulse Fuel Injector is a new type of injector utilizing solenoid control and small amounts of compressed air to provide atomized fuel for internal combustion engines for far superior efficiency and economy.

- The Jetfan: The unique design of the Jetfan harnesses the Coanda effect to provide quieter and much more efficient fan systems for both positive and negative pressure applications.

Split-Cycle Technology first began using computer design tools for its research in mid-1995, and chose MicroStation for a number of reasons. The cost of a UNIX workstation, including both the hardware and software, was prohibitive for a relatively small company like Split-Cycle Technology. MicroStation Modeler’s ability to operate on a PC platform, yet provide binary compatibility among other platforms, was important to the company. MicroStation Modeler was originally purchased to enable the generation of stereolithographic models of the extremely complex curved surfaces of the Jetfan. However, the company quickly recognized MicroStation Modeler’s abilities for the precise generation of models for the Split-Cycle Technology engine and the minute clearances of the Pulse Fuel Injector.

MicroStation MasterPiece is also used to generate high-quality rendered images and, more importantly, the animation of engine components. The power shaft of the Split-Cycle Technology engine, although simple in theory, is extremely difficult to imagine in operation.

MicroStation MasterPiece is also used to generate high-quality rendered images and, more importantly, the animation of engine components. The power shaft of the Split-Cycle Technology engine, although simple in theory, is extremely difficult to imagine in operation.

Rick Mayne, one of the directors of Split-Cycle Technology and the inventor of the Split-Cycle engine, believes that he speed and accuracy of engineering products like MicroStation Modeler are crucial in today’s economy. Research and development, he explains, is very slow and very expensive. In the development of mechanical applications like those created by Split-Cycle Technology, components are made individually, and maintaining control of mating components for a particular model of engine has a very high margin of error. “Compound this high margin of error, ” explains Mayne, “with several models, each slight different from each other, and it becomes a nightmare.”

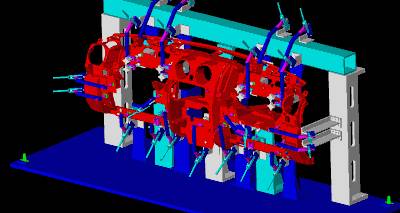

Split Cycle engine parts, modeled and rendered in 3D Artist.Mayne believes that the company’s choice of engineering software is a simple matter of economic principles. “If you get the second best you will always have second best,” he explains, “and this applies to hardware, software, and people.” He warns other companies that the savings forecasted by selecting the right engineering software will not materialize if they choose the wrong software.

MicroStation Modeler was the right choice for Split-Cycle Technology. The company is now able to engineer as design and have it “running” on screen at a fraction of the cost and time of workshop prototyping. According to Mayne, with the ability to evaluate an idea for a product or component early in the design process, “only the very best ideas ever get to the workshop lathes and mills.”

Split-Cycle Technology has found that MicroStation Modeler has made an enormous difference in its productivity and efficiency. “The old ways (in which Split-Cycle Technology designed components) were slow, expensive and had a high risk factor” said Mayne. “The new ways are faster, cheaper, and have less risk,.” He also explains that MicroStation Modeler has helped Split-Cycle Technology develop a higher level of professionalism, not only for itself, but also the contractors and suppliers the company uses. “Our ability to forecast the supply of stock, materials, components and services well in advance of our needs makes life a lot less stressful for all,” said Mayne.