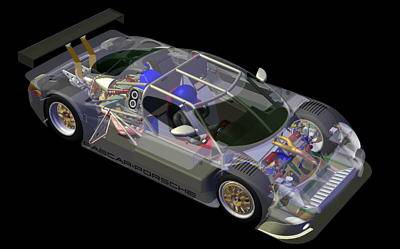

The Los Angeles Auto Show was the venue for the world premiere of Volkswagen’s latest concept vehicle. The two-seat, three-wheel GX3 is a radical departure from the ordinary. This crossover between sports car and motorcycle promises a unique driving experience and lots of head turning.

The Los Angeles Auto Show was the venue for the world premiere of Volkswagen’s latest concept vehicle. The two-seat, three-wheel GX3 is a radical departure from the ordinary. This crossover between sports car and motorcycle promises a unique driving experience and lots of head turning.

Down to the smallest detail, nothing about the GX3 is ordinary. Typifying the design goals is the stainless steel shifter knob that Volkswagen calls its “center jewel”. According to Volkswagen North America’s chief designer, Derek Jenkins, show attendees were intrigued by the shifter knob and were prone to ask “How did you do that?” which is exactly what VW Design Center team wanted. The answer to the question is Direct Metal Laser- Sintering (DMLS) from EOS.

Based on the response at the Los Angeles Auto Show, it appears that Jenkins and his design team have exceeded this goal. As the design of the GX3 began taking shape, attention shifted to the shifter knob. The design team wanted something extraordinary, so it set out to put a modern twist on the VW Golf GTI’s golf ball-shaped shifter knob. Leveraging modern technology, the designers conceived of a hollow, lightweight appearance that retained the design form of the GTI shifter knob. To support the interior cockpit design, VW also wanted a metallic finish that matched the trim and accents.

VW’s GX3 concept vehicle blends the driving excitement of a sports car and motorcycle. To make the vision come alive, the design team turned to DMLS for the manufacture of a 17–4 stainless steel shifter knob made on an EOSINT M 270 system. VW knew that CNC machining could not produce the design and other rapid prototyping and manufacturing systems could not deliver the look and feel that the company wanted. According to Jenkins, “If it weren’t for the EOS technology, we would have had to scrap the design and gone with a shifter knob that had less impact. EOS was the only option that we saw.”

VW’s GX3 concept vehicle blends the driving excitement of a sports car and motorcycle. To make the vision come alive, the design team turned to DMLS for the manufacture of a 17–4 stainless steel shifter knob made on an EOSINT M 270 system. VW knew that CNC machining could not produce the design and other rapid prototyping and manufacturing systems could not deliver the look and feel that the company wanted. According to Jenkins, “If it weren’t for the EOS technology, we would have had to scrap the design and gone with a shifter knob that had less impact. EOS was the only option that we saw.”

Delivered with a shot peened finish, Volkswagen turned the shifter knob on a lathe and tapped a hole for a set screw. The reason for turning the shifter knob was, in part, that VW wanted a machined finish that matched the appearance of the other metallic cockpit components. Jenkins stated, “I was amazed at how well it machined. It was fully dense with the properties of billet material.”

Jenkins cites the shifter knob as an example of the technology freeing the design team’s creativity. “Without this technology, our designs were constrained, even limited, by what traditional manufacturing technologies could produce,” stated Jenkins. He also commented that, due to tooling costs, the design team would face opposition anytime it specified an injection molded part. These comments elicited Jenkins’ musing of the future, “With this technology, will anyone be injection molding parts ten years from now?”

Jenkins cites the shifter knob as an example of the technology freeing the design team’s creativity. “Without this technology, our designs were constrained, even limited, by what traditional manufacturing technologies could produce,” stated Jenkins. He also commented that, due to tooling costs, the design team would face opposition anytime it specified an injection molded part. These comments elicited Jenkins’ musing of the future, “With this technology, will anyone be injection molding parts ten years from now?”

In the future, for large-scale production demands, Jenkins acknowledges that injection molding, die casting and similar high-volume processes will still be needed. However, he does predict that industry is moving towards e-Manufacturing, the fast, flexible and cost-efficient production directly from CAD data.

“Rapid prototyping has come a long way since the early days when it was exotic and expensive. It is now a standard part of the design process,” Jenkins said. He foresees, and is anxiously awaiting, the same developments in e-Manufacturing. “I believe that the technology will progress from a prototyping tool to a manufacturing process.” He also commented that he expects that EOS will be a company that helps the dream become reality, and he sees that parts of the dream are already coming true. “This is the future of manufacturing,” exclaimed Jenkins.

Volkswagen is planning an extensive accessory program that will let owners customize and personalize their GX3s. Should the GX3 become a staple on dealer lots, and when the accessory program kicks in, Jenkins believes that VW, or a third party, will likely offer DMLS shifter knobs in stainless steel, titanium or any other material that EOS has available. When this happens, it will be one more example of DMLS as an e-Manufacturing process.

Volkswagen is planning an extensive accessory program that will let owners customize and personalize their GX3s. Should the GX3 become a staple on dealer lots, and when the accessory program kicks in, Jenkins believes that VW, or a third party, will likely offer DMLS shifter knobs in stainless steel, titanium or any other material that EOS has available. When this happens, it will be one more example of DMLS as an e-Manufacturing process.

Volkswagen’s decision to make the GX3 a production vehicle hinges on the response from the market. While no determination has been made, the reaction it received at the Los Angeles Auto Show has made the prospects of a 2007 launch of the GX3 very attractive. So, as early as next year, this crossover vehicle may be cruising around the suburbs and cities, and it may be personalized with a stainless steel shifter knob.

In the meantime, Derek Jenkins and his design team are busily working on new designs and new concepts. While outsiders can only guess at what they will come up with, one thing is for sure, the team will be using DMLS. Jenkins said, “Without question, we will be using EOS on our future projects.”

Images courtesy of Volkswagen