Italians are passionate about their motorcycles. The streets and roads of Italy are choked with every kind of two-wheeled conveyance you care to imagine.

From the ubiquitous motor scooters that seem to be absolutely everywhere, to the throbbing Ducati that passes you on the ‘autostrada’ in a blur of color; it seems that just about everybody in Italy has a motorcycle of some kind.

Sergio De Pretto is a guy who is more passionate than most about his motorcycles. Back in the 1970s he began making special accessories and replacement parts to dress up the bikes he was stripping down and customising — bikes that would ultimately become works of art on two wheels. In Italy, as in many other countries, many riders like to dress up their bikes and the demand for stylish, high-quality custom parts is high. His bikes were well-received by other enthusiasts and a market for his custom accessories grew. Sergio De Pretto, wife Stefania Filippi and staff Sergio De Pretto (left) and wife Stefania Filippi (second from left) are involved with every facet of the manufacturing business from design through to marketing.

Then, 24 years ago, Sergio De Pretto found that his passion for remodelling motorcycles had become a full-time occupation. Together with wife Stefania, Sergio has created a booming business designing and manufacturing motorcycle accessories and replacement parts. Today De Pretto Moto offers a vast range of more than 3,000 individual parts to dress up many motorcycle models from such famous manufacturers as Ducati, Yamaha, Suzuki, Honda, Kawasaki, Moto Guzzi and Harley Davidson. The range of products is sold across throughout Europe, USA, the Middle East and Asia/Pacific.

Then, 24 years ago, Sergio De Pretto found that his passion for remodelling motorcycles had become a full-time occupation. Together with wife Stefania, Sergio has created a booming business designing and manufacturing motorcycle accessories and replacement parts. Today De Pretto Moto offers a vast range of more than 3,000 individual parts to dress up many motorcycle models from such famous manufacturers as Ducati, Yamaha, Suzuki, Honda, Kawasaki, Moto Guzzi and Harley Davidson. The range of products is sold across throughout Europe, USA, the Middle East and Asia/Pacific.

The De Pretto Moto company is based in the community of Caldogno, in north-eastern Italy’s Veneto region and close to the industrial city of Vicenza. The operation consists of a factory with office, a showroom and warehousing facilities.

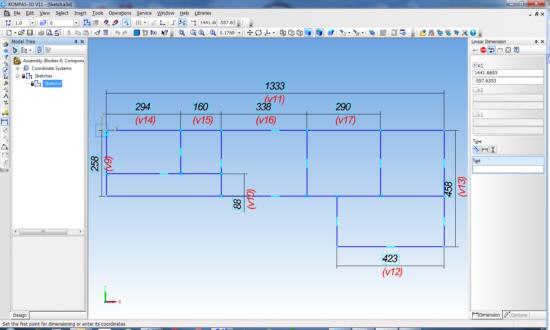

Sergio takes a hands-on approach to everything in his business. As the chief designer he loves to get his hands dirty stripping down each new model selected for customisation. Models are selected on the basis of popularity so as to ensure a strong demand for the custom product line. The parts to be given the De Pretto Moto treatment are decided on as the motorcycle is pulled down. The original parts reverse engineered to determine dimensional and functional specifications. Although CAD/CAM tools are used extensively in the process just prior to machining, much of the design process is conducted with paper and pencil, allowing the designers to get a better feel for the final look of the component. Ultimately, the designs are defined in 2D and 3D drawings and processed with Virtual Gibbs en route to the CNC machine shop.

The De Pretto machine shop is impressively equipped with bar-fed CNC turning centers, CNC milling machines and a CNC laser cutter. Most finishing operations are also done in-house although small parts assembly and anodising tasks are outsourced to local specialists.

The De Pretto machine shop is impressively equipped with bar-fed CNC turning centers, CNC milling machines and a CNC laser cutter. Most finishing operations are also done in-house although small parts assembly and anodising tasks are outsourced to local specialists.

DPM staff running the bar-fed CNC turning centers DPM staff run the bar-fed CNC turning centers around the clock, continuously producing complex machined components.

To walk through the machine shop is an education in itself. The turning centers sit there slurping in bar-stock like strands of spaghetti and spitting out finished components at the other end. The most complicated parts required up to 60 tool changes to complete. All parts are fully machined from solid stock and no molding operations are employed at any stage. The obvious benefit is the elimination of high tooling design and production cost for molding dies, molding plant investment and absence of additional molding and molded product finishing stages. The deployment of multi-axis turning centers provides vast scope for automated production of complex parts. Most parts are machined from aluminum alloy There is also a certain attractive, crisp definition to parts machined out of solid stock that is impossible to obtain in molded parts.

Machining runs are planned to wring the maximum efficiency out of material supplies and machine time. Finishing operations are done on a ‘just-in-time’ basis in order to fulfil orders or replenish warehouse stock levels; which are also maintained at optimum numbers based on historical information.

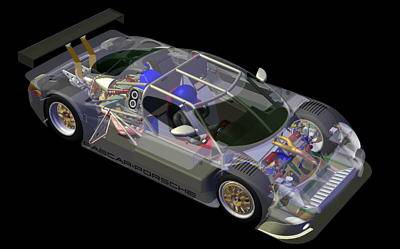

The latest feather in the De Pretto cap is a recent agreement to design, manufacture and supply the official range of accessories and special parts for the Special Ducati Monster 900 street machine. The Special is the sports-dressed version of the Ducati Monster 900 motorcycle. The Monster is impressive enough as it comes standard from the factory, but dressed up with De Pretto parts, the Special is truly something else. With Ducati’s blessing, all special accessories for the Special include both the Ducati and De Pretto Moto marks. Recognition indeed that De Pretto Moto has what it takes to be counted with the best in world-class motorcycling.

The latest feather in the De Pretto cap is a recent agreement to design, manufacture and supply the official range of accessories and special parts for the Special Ducati Monster 900 street machine. The Special is the sports-dressed version of the Ducati Monster 900 motorcycle. The Monster is impressive enough as it comes standard from the factory, but dressed up with De Pretto parts, the Special is truly something else. With Ducati’s blessing, all special accessories for the Special include both the Ducati and De Pretto Moto marks. Recognition indeed that De Pretto Moto has what it takes to be counted with the best in world-class motorcycling.

Special Ducati Monster 900 Detail of the Special Ducati Monster 900 with De Pretto Moto designed and manufactured accessories and sports-detailed replacement parts.

CAD tools do not feature strongly in the De Pretto Moto design office. No one would dispute that Italian designed and manufactured goods have in the past and continue today to consistently set very high standards for others to match. At De Pretto as with other manufacturers I visited in Italy, CAD tools are used where they are considered valuable and make an essential contribution to the quality or efficiency of production, but this is by no means taken for granted.

CAM software is very highly regarded in achieving optimum production from CNC machinery. There is typically no hesitation to use CAM tools where the benefits are clear and obvious. Great store is still placed in the experience and skill of the designers, toolmakers and production staff. While CAD vendors everywhere are extolling the necessity of this or that product to reduce time to market or some other indispensable idea, it is clear that users of such software do not have exclusivity over quality and style in design or efficiency in design cycles and production runs. It is refreshing and encouraging to see machine rooms like DePretto’s turning out first rate products quietly and profitably with a moderate use of high technology in the design stage.