With more than 25 years experience in designing and manufacturing karts, Drew Price Engineering took on the challenge last year of driving the business forward into the third dimension. Using Autodesk Inventor 3D design software DPE increased the design and development performance of their karts – paying dividends at the track.

With more than 25 years experience in designing and manufacturing karts, Drew Price Engineering took on the challenge last year of driving the business forward into the third dimension. Using Autodesk Inventor 3D design software DPE increased the design and development performance of their karts – paying dividends at the track.

DPE designed karts took out four of the top ten positions at the 2002 Rotax Max Challenge Grand Finals in Malaysia. Contested by 75 drivers from 29 countries, first place winner, South African Claudio Pallazza-Musso drove a DPE designed kart as did Australian Darrell Smith who topped the ranks in the +35 years category.

Design Cycle Tightens

Karts differ from other vehicles in that they have no visible suspension. The trick to a good kart is ensuring that the framework will allow a bit of give and take on the track.

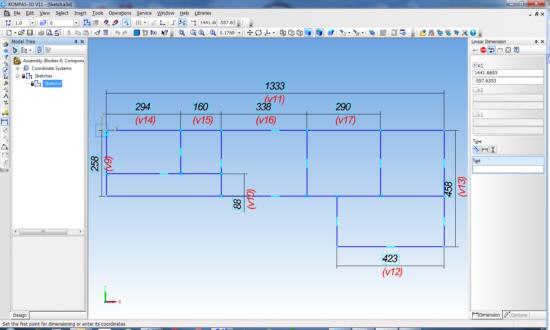

Designing such a frame is a time consuming process, as designs need to be continually created, tested and revised. Intelligent 3D software such as Autodesk Inventor allows both major and minor revisions to be made in the early stages of the design, eliminating the need to make major changes later in the engineering cycle.

Designing such a frame is a time consuming process, as designs need to be continually created, tested and revised. Intelligent 3D software such as Autodesk Inventor allows both major and minor revisions to be made in the early stages of the design, eliminating the need to make major changes later in the engineering cycle.

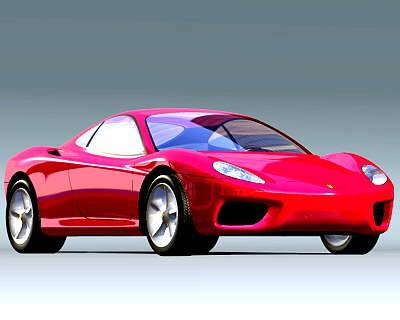

The time saved on making these revisions can then be reinvested in work done on the aesthetics of the kart, ensuring it achieves the sleek, professional look of an A-grade kart.

Exterior bodywork detailing is conducted using the digital 3D model. Simulated materials such as steel, aluminium, plastic and fiberglass are employed and manipulated to create a realistic image of the end product.

Put Through Its Paces

Automated drawing production is not unusual in the automotive design industry. What is interesting however, is that DPE integrated the designs in Autodesk Inventor with Cosmos, a mechanical testing program.

Sharing the digital design data between Inventor and Cosmos, loads and forces are applied to the chassis, rigorously testing its strength, flexibility and durability.

Modifications made to the plans in Cosmos are automatically fed back to Inventor where the intelligent design data updates itself accordingly.

This process ensures that the components are road-worthy before physical models are even required. The need for prototyping and physical testing is therefore reduced, saving DPE and customers both time and money. More importantly, this means the karts produced by DPE maintain and improve their reputation for good quality. Making Life Easy for Marketing

This process ensures that the components are road-worthy before physical models are even required. The need for prototyping and physical testing is therefore reduced, saving DPE and customers both time and money. More importantly, this means the karts produced by DPE maintain and improve their reputation for good quality. Making Life Easy for Marketing

Based in Melbourne, DPE currently exports its award-winning karts and karting products to 15 countries around the world, including the US, UK, Canada and Japan.

For DPE, the 3D digital designs extend beyond the engineering team, helping the company to market its karts overseas.

According to Drew Price, managing director of DPE, “International clients are able to see the finished product on the screen in front of them and are assured of the kart’s functionality before they even lay hands on a physical model.”

With success in the USA, Japan, Australia, New Zealand and the Oceania Championships, Arrow AX# karts and DPE products are becoming more and more recognised all over the world.

In their large, modern kart design and manufacturing facility in Melbourne, Australia – possibly the largest outside Europe – they carry out most work ‘in-house’. This ensures the highest quality is achieved and maintained. Their unique combination of modern technology, engineering ingenuity and clever design provide an unparalleled platform from which to design and manufacture some of the very best karts and karting products.

In addition to Arrow AX# karts, DPE also have its own exclusive ‘Kartech’ range of karting equipment, which comprises driving apparel, promotional items, tools, engine and exhaust components, seats and sprockets – just to mention a few! DPE are also agents and distributors for many of Australia’s and the world’s best karting components, including being the sole Australian importer of Bridgestone kart tyres and Rotax kart engines.