The Franke Group plans, develops, and produces kitchen and restaurant installations for restaurant chains worldwide and is the world leader in this sector. The international group has four areas of business:

The Franke Group plans, develops, and produces kitchen and restaurant installations for restaurant chains worldwide and is the world leader in this sector. The international group has four areas of business:

- Kitchen systems – sinks, drains, fittings, and so forth

- Contract Group – which equips restaurant chains and their kitchens

- Beverage containers – beer kegs and soft drink containers

- Various products – cooking appliances and catering equipment for restaurants and the catering industry, coffee machines for restaurants, and metal construction in stainless steel and turbine parts

The CAD Standard

In 1998 the Contract Group decided to make Autodesk® software the company standard worldwide. Autodesk products have now become the focus of an overall solution from ERP, EDM, CAD, and machine control software, and they form an important milestone on the way to an international design database.

Architecture First

Architectural plans are considered first and foremost when planning a restaurant. The company receives these plans from the customer, often in digital form. Its business partners in the United States use Autodesk software, so Franke decided to introduce the company’s software.

Today, Autodesk® Architectural Desktop is generally used for planning room layouts. Many sales advisers have installed the software on their laptops and can plan a kitchen installation with the customer on site.

The company also uses Autodesk® VIZ, and one staff member has specialized in producing walk-throughs of kitchen designs so that customers have a better basis on which to make a decision.

Fittings

Franke manufactures stainless steel kitchen fittings¾ cupboards, appliance surrounds, work surfaces, and cup dispensers. Until the late 1990s, 2D CAD software was used for designing these steel parts.

Franke manufactures stainless steel kitchen fittings¾ cupboards, appliance surrounds, work surfaces, and cup dispensers. Until the late 1990s, 2D CAD software was used for designing these steel parts.

Industrial kitchen workspace design by Contract Group Industrial kitchen workspace design by Contract Group

The company sought an AutoCAD®-based solution to replace this system in order to maintain the architectural and design information in the same data format. The new system also had to allow 3D design. Autodesk® Mechanical Desktop® software met all the requirements, combined with DataM’s Copra Metal Bender for sheet metal design.

An added benefit was that the company could reduce training costs by drawing on the wide base of engineers and drafters worldwide familiar with AutoCAD software.

Legacy File Conversion

Whether designing a kitchen for a new customer or fitting out a restaurant for a current customer, designers generally start with existing elements. Therefore, the 3D system needed to incorporate the company’s 30,000 legacy drawings. The system supplier, CAD-LAN AG from Suhr (Switzerland), provided the conversion service. Overall Solution

CAD-LAN was also crucially involved in the structure of the overall solution. To improve the organization of the design processes, the AutoManager Meridian document management system from Cyco was chosen when Autodesk Mechanical Desktop was first introduced.

CAD-LAN adapted the program to Franke’s specific requirements and connected the CAD program to the ERP system. Autodesk Inventor®

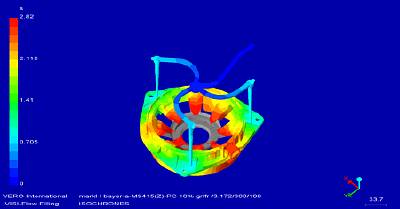

Autodesk Inventor offers several advantages over Autodesk Mechanical Desktop for Franke designers: integrated sheet metal functions mean applications such as Copra Metal Bender are not necessary. In addition, in-house tests showed that staff learn Autodesk Inventor more quickly. The program also offers the same options as Autodesk Mechanical Desktop for connecting adjacent systems (PPC, EDM, and Production).

With this knowledge, the Contract Group decided to upgrade to Autodesk Inventor; locations not yet using Autodesk Mechanical Desktop will implement Autodesk Inventor.

3D Is the Answer

“It’s true that we only use a small proportion of the functions provided by a 3D CAD system,” acknowledges Markus Bierl, IS Director with the Franke Contract Group. “But the advantages are indisputable.”

Bierl is referring to the ability to produce assemblies on the computer and check whether all the parts have been planned correctly, long before any prototypes are produced.

3D drawings have also proven to be an advantage in production. Designers can use 3D drawings to get a better idea of how the finished part should look and therefore make fewer mistakes.

The Goal: Worldwide Design

If all design locations use the same tools, Franke can build a worldwide design database that is accessible to all its engineers. There will then be less redundancy in the development stage, and in the event of capacity bottlenecks, work can be outsourced to any Franke location. Both Autodesk and Cyco support this distributed method of working in their product development.

“We have not pursued standardization for the sake of it,” summarizes Christian Sperka, Franke Group CIO. “We have chosen systems that support our way of working and can take us forward into the future.”