Buying bottled water has become a part of everyday life for most people, but not many people stop to think about the complexity involved in bottling and distributing water and other bottled beverages to millions of consumers worldwide. One company did. Dyco Inc. of Bloomsburg, Pennsylvania took on the complex issue of figuring out how to efficiently pack bottles for storage and shipment, and develops the automated equipment that solves this problem. Dyco has been the leader in handling plastic containers for three decades.

In 1973, Dyco began solving the complex handling tasks of plastic containers for an ever-increasing number of products. Dyco evolved from the commercial blowmolding industry to the design and development of equipment that automates the process of packing bottles for storage and shipment. Today, Dyco’s machines have become the industry standard for handling lightweight plastic containers in the dairy, juice and water industries.

At Dyco, machine design is by committee, bringing together a group of experienced mechanical, electrical, and design engineers, computer programmers, and production personnel to develop systems that meet the individual requirements of their customers. Dyco offers its clients fast project turnaround and an exceptional level of quality by keeping all the designing, engineering and manufacturing in-house. Its engineers study a client’s operation and future plans to ensure the result improves their overall productivity.

At Dyco, machine design is by committee, bringing together a group of experienced mechanical, electrical, and design engineers, computer programmers, and production personnel to develop systems that meet the individual requirements of their customers. Dyco offers its clients fast project turnaround and an exceptional level of quality by keeping all the designing, engineering and manufacturing in-house. Its engineers study a client’s operation and future plans to ensure the result improves their overall productivity.

Dyco Outgrows 2D Software

As Dyco expanded and began designing and manufacturing more complex and sophisticated products, they realized that a 2D design system was no longer going to offer them the technology or productivity they needed to deliver products on time and on budget. In addition, with the lack of visualization capabilities in 2D software, Dyco was forced to assemble costly prototypes before production to identify any last minute errors or design flaws. In fact, the first time the design was actually seen was on the shop floor, which meant that last minute corrections were time consuming and expensive.

On average, it took Dyco four days to assemble a machine. Every assembler needed a drill and a tape measure to complete the job. Assemblers had to drill holes in the sheetmetal in order to ensure that the holes of the various parts lined up for bolting. Overall, machine customization was slow and error prone — drawings did not get updated, mistakes were made redrawing and recalculating flat patterns, and only one or two people knew the placement of every part. Autodesk Inventor stands out from the competition

Dyco conducted an extensive evaluation of several 3D mechanical design solutions including Autodesk Inventor, Pro/Engineer and SolidWorks. Enlisting the help of Synergis Technologies (www.synergis.com), the single largest AutoCAD-based solutions provider in the mid-Atlantic region and an authorized Autodesk Systems Center (ASC) for manufacturing and other industries, Dyco concluded that Autodesk Inventor 3D design software was the most powerful and the easiest to use of all three competitors’ products. In addition, Synergis was able to provide 3D software integration and training for the entire company.

Dyco conducted an extensive evaluation of several 3D mechanical design solutions including Autodesk Inventor, Pro/Engineer and SolidWorks. Enlisting the help of Synergis Technologies (www.synergis.com), the single largest AutoCAD-based solutions provider in the mid-Atlantic region and an authorized Autodesk Systems Center (ASC) for manufacturing and other industries, Dyco concluded that Autodesk Inventor 3D design software was the most powerful and the easiest to use of all three competitors’ products. In addition, Synergis was able to provide 3D software integration and training for the entire company.

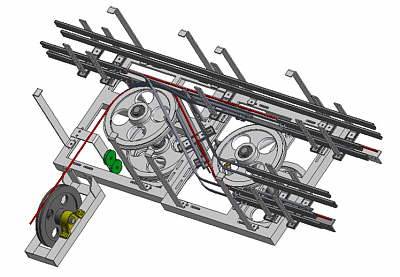

Autodesk Inventor software stood out from the competition in terms of ease of use, large assembly management, and the ability to reduce costs while speeding concept-to-manufacturing cycle time. Synergis proved to Dyco that Autodesk Inventor could handle its assemblies comprised of several thousand unique parts. Using Autodesk Inventor, large assemblies can be loaded quickly and manipulated effectively due to the software’s adaptive data engine, a high-performance segmented database, and assembly-centric design. The software also allows Dyco to design parts in 2D or 3D, assemble them, move them, and complete the conceptual design in a mixed 2D/3D environment before creating 3D parts.

A streamlined user interface, an advanced help and support system, and an intuitive workflow are cornerstones of Autodesk Inventor software’s ease of use. Both in-house designers and engineering student interns who are regularly brought in to work at Dyco can be productive in less than a day. In addition, Synergis was able to offer Dyco flexibility in their training, providing a tailored course at Synergis’ office in Quakertown, Pennsylvania.

A streamlined user interface, an advanced help and support system, and an intuitive workflow are cornerstones of Autodesk Inventor software’s ease of use. Both in-house designers and engineering student interns who are regularly brought in to work at Dyco can be productive in less than a day. In addition, Synergis was able to offer Dyco flexibility in their training, providing a tailored course at Synergis’ office in Quakertown, Pennsylvania.

“With the introduction of Autodesk Inventor, Dyco is experiencing fewer design errors and has increased their design capabilities. As a team, Dyco, Autodesk, and Synergis were able to work together to meet Dyco’s engineering objectives,” said Mark Mahovich, director of Mechanical Solutions at Synergis Technologies.

According to Ron Cordingly, lead engineer at Dyco, “Autodesk Inventor is extremely easy to learn. As a result, we have brought people up to speed very quickly. In fact, we see payback every day.”

Precision Design for Machine Assembly

Autodesk Inventor software affords Dyco the ability to design in 3D, establishing precision dimensions. It’s compatible with the downstream manufacturing software which drives the laser cutter on the production floor, allowing for accurate, cost effective, machine assembly. With the click of a button, the designer can use the software to create a flat pattern of the part for cutting the sheet metal out on a laser machine. The company integrated Autodesk Inventor with CNC manufacturing to increase productivity and accuracy on the shop floor. High quality assembly drawings are created very rapidly. Machines now go together and function the first time without any bending, cutting or drilling — a first for Dyco.

“Autodesk Inventor enabled us to reduce assembly time of the machine by 75 percent while making it more economical, functional and serviceable,” said Pete Yohe, president of Dyco Inc. “Autodesk’s claims of ‘single day productivity’ are true.”

“Equipment now goes together like a jigsaw puzzle. It is truly amazing,” added Mark Wolford, shop floor manager at Dyco Inc.

“Equipment now goes together like a jigsaw puzzle. It is truly amazing,” added Mark Wolford, shop floor manager at Dyco Inc.

Today, Dyco engineers spend less time documenting and drafting. Plus, human error is nearly eliminated. The increase in productivity gives Dyco more time to design for serviceability, functionality and economy.

As an additional benefit, Dyco’s sales force can leverage the Autodesk Inventor design information for sales brochures, marketing collateral and client presentations. They are also using the capabilities of Autodesk Inventor to enter into new markets such as fitness equipment, serving as a contractor for design and manufacturing. Better Communications with Customers

Using Autodesk Inventor 3D software, Dyco drastically improved communication with customers. Autodesk Inventor lets them show the customer the entire machine on the computer, rather than printing out numerous drawings, and they can automate the machines mechanisms on screen to communicate its abilities more clearly. The software allows Dyco to rotate, zoom, pan, take apart and put together the machine in front of the customer’s eyes. The entire engineering team can now review designs and customize or modify equipment for customers quickly and accurately.

Complex designs are now possible, designs that in 2D would be too hard to design accurately.

So now when you reach for that bottled water, you know that a lot of powerful technology helped in the process to bring that bottle to you.