The concept of producing material objects from 3D CAD is commonly known as Rapid Proto-Typing, or ‘RPT’. It has had quite a short history, but has seen many new technologies introduced in that short time. The first process, called stereolithography, used a vat of liquid polymer plastic which was hardened in layers by a laser to create a solid plastic object. The liquid material was a very expensive item, the process very slow, and it needed a controlled environment room. The cost of both machine and material kept the process to a few bureaux and research institutions.

The concept of producing material objects from 3D CAD is commonly known as Rapid Proto-Typing, or ‘RPT’. It has had quite a short history, but has seen many new technologies introduced in that short time. The first process, called stereolithography, used a vat of liquid polymer plastic which was hardened in layers by a laser to create a solid plastic object. The liquid material was a very expensive item, the process very slow, and it needed a controlled environment room. The cost of both machine and material kept the process to a few bureaux and research institutions.

Many other technologies followed, usually offering faster and cheaper operation. One particular system (LOM) uses sheets of paper that are laser cut and laminated. All processes have their advantages and disadvantages and those that have stood the test of time have some particular characteristic that gives them a market niche.

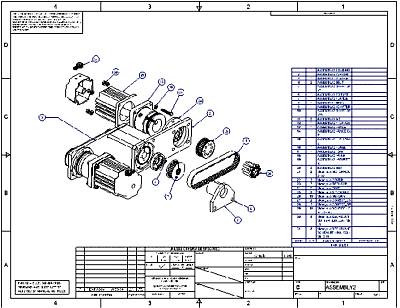

All systems are based on the idea of taking a computer 3D model and calculating paper-thin slices through it, so that the data represents a laminated model. This laminated-model data is then output layer-by-layer to the machine to solidify, fuse or cut material for each lamination. A standard now exists for the lamination model data – the STL file format – and virtually all 3D manufacturing CAD systems can now generate STL files. This makes it easier for designers to interface with a variety of machine systems than was the case in the early days of Rapid Prototyping.

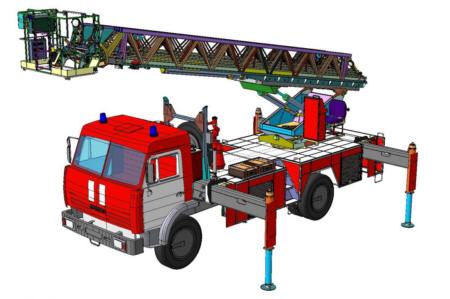

A US company, Z-Corporation, has developed a Rapid Prototyping machine that offers a very attractive combination of features. It uses extremely cheap material, operates very quickly and does not need elaborate special environments. The machine is based on inkjet printer head technology and so has been labeled a “3D Printer”. The only downside aspect of the machine is that the models produced are not as strong as from some other systems. So, although they cannot serve as short-term mechanical working components, they do provide very good quality, highly detailed objects that are ideal for design-team and client evaluation. They can be handled quite roughly, and can be finished to a good surface and receive paint or other coloring treatments. The objects can even include separate internal objects.

The machine applies a precisely controlled thin layer of material in powder form to the building platform, then the head traverses over the layer like a print head, squirting binding liquid (like thin glue) onto the powder layer. This solidifies the powder where it is applied. When one layer has been traversed and solidified, the bed drops by one layer thickness, another layer of powder is applied and the process repeated for all layers, bottom to top. The material can be either a form of talcum powder or a flour substance. The model is contained within an enclosure so that un-fused powder inside and outside the solidified material is held in place and serves to support the next layer if it overhangs the layer below. After building a model, un-fused powder is collected and can be re-used.

The machine applies a precisely controlled thin layer of material in powder form to the building platform, then the head traverses over the layer like a print head, squirting binding liquid (like thin glue) onto the powder layer. This solidifies the powder where it is applied. When one layer has been traversed and solidified, the bed drops by one layer thickness, another layer of powder is applied and the process repeated for all layers, bottom to top. The material can be either a form of talcum powder or a flour substance. The model is contained within an enclosure so that un-fused powder inside and outside the solidified material is held in place and serves to support the next layer if it overhangs the layer below. After building a model, un-fused powder is collected and can be re-used.

Most layer-building machines such as those that build by solidifying liquid polymer by laser action, require temporary support webs to be designed in the 3D modeling, to support hollow or overhanging shapes, and those need to be broken off and smoothed later. In the Z-Corp machine, because the material is powder, the un-glued powder is closely enough packed to support the structure while being built. Hence temporary supports are rarely needed. Any entrapped powder is easily washed away after building. This capability is strikingly demonstrated by various objects that have internal objects within them, all built in one operation.

This system is also good for making investment-casting models, where the model is used to cast a mould and then dissolved so that the final product can be cast in its place.

RPT is now being used considerably to assist in various types of surgery. For example, it is being used for creating solid models of patient’s skulls from CAT scan data (which is also in the form of lamination data). The 3D slice data is reprocessed into STL form and a replica of the patient’s skull created with the 3D Printer. Then the surgeons can work out exactly what needs to be done and have any prosthetic parts made before the patient has to go under anaesthetic or suffer preliminary exploratory surgery. Another common use is for hip replacement surgery, where it allows the prosthetic parts to be accurately manufactured prior to doing any surgery.

RPT is now being used considerably to assist in various types of surgery. For example, it is being used for creating solid models of patient’s skulls from CAT scan data (which is also in the form of lamination data). The 3D slice data is reprocessed into STL form and a replica of the patient’s skull created with the 3D Printer. Then the surgeons can work out exactly what needs to be done and have any prosthetic parts made before the patient has to go under anaesthetic or suffer preliminary exploratory surgery. Another common use is for hip replacement surgery, where it allows the prosthetic parts to be accurately manufactured prior to doing any surgery.

For evaluation of product design, since with this Z-Corp machine most models can be printed in just a few hours, a designer can create a concept, ‘print’ it, observe defects when handling the object or get feedback from clients, correct it, reprint it, make improvements, and print it a third time for design review all in the same day. Many other processes take overnight or more than a day to produce a product, and most are too costly in material to allow trial-&-error methods.

Parts can be given a variety of different qualities depending on the intended use. They can be infiltrated with a wide variety of substances to give them strength and other characteristics, such as temperature and water resistance or color.

The details of the Z402 machine’s size limitations and performance are as follows:

- Build Speed: Between 25 and 51mm vertically per hour, depending on build density

- Build Volume: 203 x 254 x 203mm

- Layer Thickness: User selectable at the time of printing. 0.076 — 0.254mm

- Equipment Dimensions: 740 x 910 x 1070mm

- Equipment Weight: 136kg

Australian & New Zealand Designers

The Z-Corp products are distributed in Australia and New Zealand exclusively by Intercad.

Intercad also offers a bureau service to 3D designers, and this service is now available via the internet. Designers can send STL data files via the internet and the objects produced are then delivered or can be collected.

While this topic can be very challengeable for most people, my opinion is that there has to be a middle or common ground that we all can find. I do appreciate that you’ve added useful, relevant and rational commentary here though. Very much thanks to you ,!