A notable achievement has been made by Swiss engineer Christoph Laimer in designing and 3D printing a tourbillon “watch”.

Christoph Laimer’s working clock with a tourbillon. In case you’re not familiar with what a tourbillon is, it is a mechanical component to a watch that prevents gravity from slowing down the watch and reducing accuracy. In an era when most watches are battery operated tourbillons are pretty rare, however faux tourbillons are quite common. Read more at 3print.com…

Inspired by previous 3D printed timepieces, Laimer’s work is a great example of meticulous design and creation in spite of, or perhaps in addition to, the means by which the project was conducted.

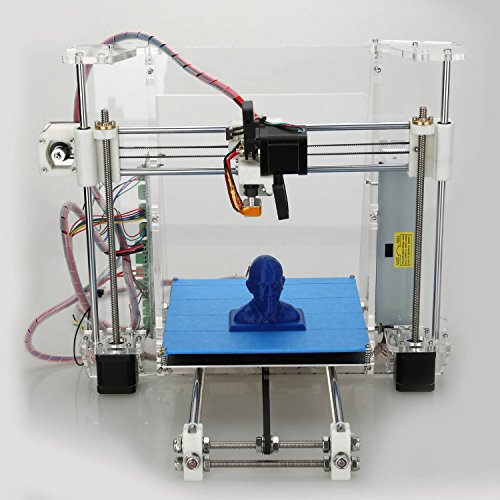

Laimer designed the mechanism parts and assembly in Autodesk Fusion 360. Exported STL files were sent to the Cura slicing engine for printing on his Ultimaker 2 desktop printer.

Because nearly the entire clock is 3D printed, this means the spring is 3D printed as well. This enormous 2 meter-long spiral of printed plastic could not have been printed without altering a few settings on the printer. The setting in question is Cura’s ‘combing’ or the ‘avoid crossing perimeters’ setting. If you don’t disable this setting, the print time increases by 30%, and moving the print head causes the plastic to ooze out over the spring. Read more at http://hackaday.com…

Assembly Animation

Assembly Timelapse

Laimer’s watch is a novel exercise in design and creation applying modern engineering tools to a 200+-year-old design rather than an example of the best way to make a timepiece. So what if it only runs for 30 minutes and is too big and inaccurate for practical use. The result is delightful and has all the charm and attraction that ingenious mechanisms and technology holds for mechanically-inclined folks.

View the parts and assembly data in Autodesk Fusion 360

Download the parts files from Thingiverse.

Introducing The World's First Fully Functional 3D Printed Watch: The Chris… https://t.co/9ZB30pC0xd via @HODINKEE

— giw_news (@giw_news) January 14, 2016