Quality product documentation is essential to ensure quality products are installed and used as the designer intended.

Dornbracht has evolved from a family firm established several decades ago into the market leader for high-quality bathroom fittings and accessories. Quality, functionality and design are the cornerstones of a corporate philosophy that encapsulates the company’s aspirations. Dornbracht celebrated its 50th anniversary in 2000 and currently enjoys the position of market leader in many countries worldwide.

Dornbracht’s quality claim is also reflected by their product documentation, such as assembly instructions. For high-quality products like the fittings of Dornbracht, both the user and the mechanic expect meaningful instructions that ensure an uncomplicated and damage-free installation.

Of course, the company wishes to meet these expectations on an international level. As the Dornbracht products are exported to many countries, the documentation must be translated into various languages. Translations, however, are often a source of error.

For the assembly instructions of the Dornbracht company, this problem has been elegantly solved. The text components in the instructions are kept deliberately small, while almost all of the assembly steps are explained through graphics. Thus, they avoid the need to explain complicated procedures and the instructions can be easily understood by all nationalities.

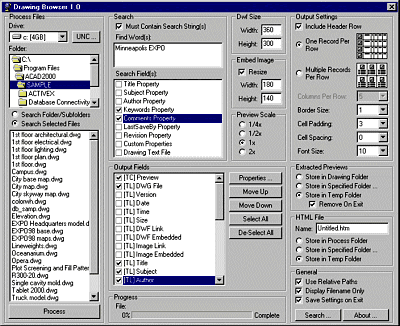

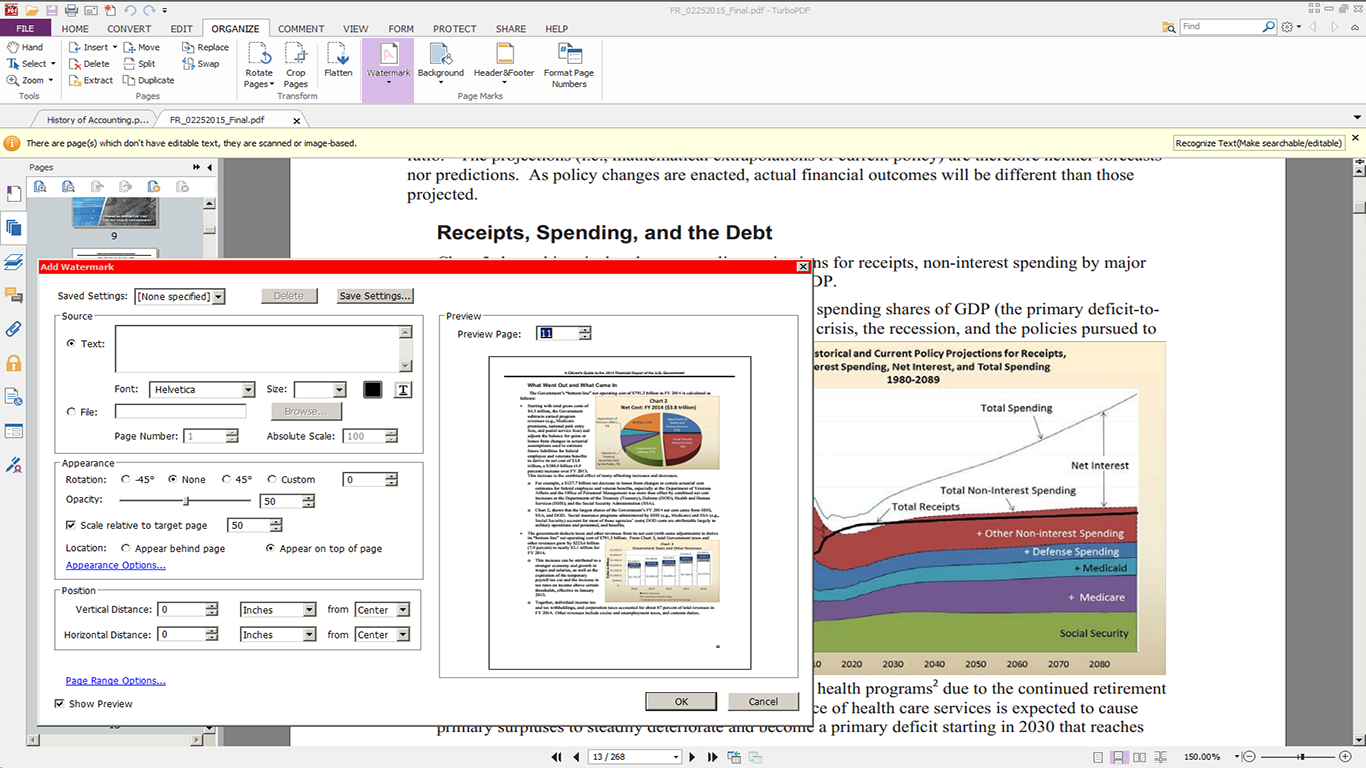

In order to ensure that the current design is depicted and to avoid mistakes that can be made when drawing from scratch, the people at Dornbracht use their design data for documentation. The 3D data from SolidWorks is automatically converted into technical illustrations with the help of IsoDraw CADprocess. The only necessary preliminary work is the export of design data to the IGES format. This can then be opened in IsoDraw CADprocess, moved into the desired position or turned, and then converted into perspective illustrations with just one click.

Usually, the completed illustrations are now ready for further use. Sometimes, minor revisions are necessary. Internal staff can easily perform these revisions. This process allows Dornbracht to pass current graphics quickly and at low cost to an external service provider, who then creates the assembly instructions and manuals. As all illustrations done in IsoDraw can be saved in a large number of export formats and therefore can be used in various DTP and publishing systems, this is a smooth data flow.

Usually, the completed illustrations are now ready for further use. Sometimes, minor revisions are necessary. Internal staff can easily perform these revisions. This process allows Dornbracht to pass current graphics quickly and at low cost to an external service provider, who then creates the assembly instructions and manuals. As all illustrations done in IsoDraw can be saved in a large number of export formats and therefore can be used in various DTP and publishing systems, this is a smooth data flow.

In addition to the time-saving factor in the creation of illustrations, the use of existing design data provides another decisive benefit for the Dornbracht company. They can begin the creation of the assembly instructions as soon as the design process is completed. Therefore, the documentation is already available in “several languages” when production begins. Furthermore, the data (graphics, dimensioned drawings) conforms to the final delivery condition, since the production department accesses the same data stock.

“With IsoDraw CADprocess, we can use our design data for documentation easily and quickly. This allows us to use more graphics in our assembly instructions, so these will match the quality demands of our company.”

Uwe Dietrich is Head of Design & Development at Aloys F. Dornbracht GmbH & Co. KG, fittings manufacturer, Iserlohn, Germany.