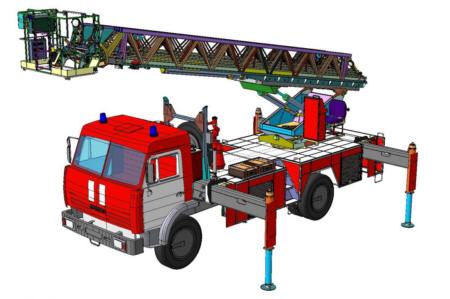

In March 2010 Engineering center of Fire Systems Co. Ltd. Brought a new product to the market – fire and rescue engine. The new truck was developed at the request of the Russian Ministry of Emergency Situations and fire services department aimed at extinguishing fire in high-rise buildings, industrial and particularly petrochemical plants.

A special feature of this fire and rescue truck is a new extension ladder with a cradle and crane capacity of three tons. This truck, the AL 34, is fully designed in KOMPAS-3D mechanical CAD solution. The crane arm is able to disassemble debris, remove obstacles from the road to get to the point of an emergency. It can also assist in the recovery of other vehicles with its winch.

“This new fire-fighting truck is much more compact and ergonomic than existing models. Another big advantage is that the price of this engine is several times lower than similar ones on the market”, – said technical director of engineering center of Fire Systems Co. Ltd., Alexander Cheremahin.

After evaluating several CAD software solutions on the market, Fire Systems Co. Ltd. chose ASCON company as a partner. The implementation of KOMPAS-3D professional solutions from ASCON began in 2005. Currently the center uses the latest version – KOMPAS-3D V11 with the newest add-ons. Each new product created in the engineering center now contains the complete virtual 3D model made in KOMPAS-3D. The solution allows designers and engineers to develop very complicated models, consisting of many thousands of parts, with minimum number of staff. The extension ladder AL 34 contains 8,820 parts. The entire project was completed by a team of just seven people, including a young specialist – la reent graduate graduate of the Technical University.

Through the use of modern and professional MCAD software solutions the design and production cycles were reduced considerably and costly error avoided. That is especially important in today’s economic situation and with the high level of competition in the marketplace. Now the team of the engineering center is able to develop new technical equipment for 4-9 months, which is much faster than before.

Through the use of modern and professional MCAD software solutions the design and production cycles were reduced considerably and costly error avoided. That is especially important in today’s economic situation and with the high level of competition in the marketplace. Now the team of the engineering center is able to develop new technical equipment for 4-9 months, which is much faster than before.

“The design of the project from the first step was made in KOMPAS-3D. That allowed us to evaluate the assembling of the project even at the concept design stage, to define dimensions, to estimate mass and centering characteristics, to calculate strength and stability, as well as considerably to reduce time of designing and number of errors”, – said designers of the project, Alexander Shalamov and Oleg Besov.

Thanks to KOMPAS-3D, in less than five years the engineering center has completely automated key processes of product design and manufacturing and has achieved a high level of visibility and collaboration across entire design team. In addition, the company has reduced design errors that previously led to costly delays and wasted materials.

With ASCON solutions Fire Systems Co. Ltd. is not only modelling products much faster, it is reusing design groundwork to maximize its return on investment. Engineers use the software to create 3D models that completely responds to their design intentions,making the fitting and rendering tests easy, as well as eliminating omissions and errors. The new fire-fighting and rescue truck from Fire Systems Co. Ltd. Is now successfully serves as reliable mate for emergency services and allows quickly to help and save more people’s lives.