Filling the space between control surfaces of an object presents a problem familiar to designers seeking to minimise mass and materials, yet provide adequate stiffness and strength to cope with the loads imposed during use. Traditional manufacturing methods have evolved time tested solutions. 3D printing or additive manufacturing methods are able to address this issue with far more organic solutions that would be impractical, if not impossible with traditional methods.

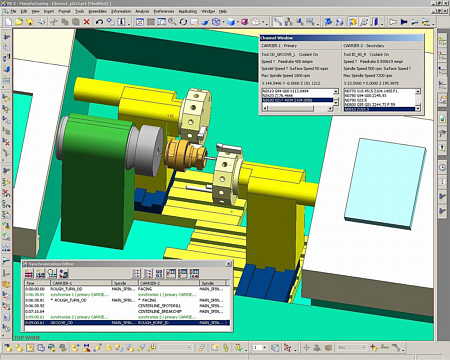

Autodesk Within is a relatively new software application that addresses the issue of filling void spaces with a structural core. Not only does it produce effective mechanical results, the output also has an artistic quality that transcends the the norm in mechanical design.

Autodesk has announced the availability of Autodesk Within, a set of generative design software solutions to help engineers create and 3D print lightweight designs for the automotive, aerospace, industrial equipment and medical implant industries. Autodesk Within is built around a powerful optimization engine that takes input parameters such as desired weight requirements, maximum stress and displacement then generates designs with variable-density lattice structures and surface skins to meet exact specifications. The resulting components are higher performing and can be considerably lighter weight than traditional designs.