The core competency of DMC Mold & Tool begins at the front end of a project during the part design phase for manufacturability where the customer and supplier communication is most important.

The design and manufacturing team at DMC Mold & Tool implement their methodology based on experience which typically has included; complex tolerance scheme’s, insert interchangeability, over molding, or decoration (IMD) considerations. The company’s customers are primarily custom plastic molders such as Nypro Inc., Seaquist Perfect and Ironwood Industries, Inc. Their customers are such names as Research In Motion, Palm One, Kyocera, Whirlpool, Baxter, and Cardinal Health.

Dustin Carlson is DMC Mold & Tool’s president and owner. He says highest among the challenges of designing and building molds is maintaining customer requirements such as adhering to their quoted cycle time along with helping to reduce runner volume while continuing to produce quality products. “Typically, we work with the closely with customer to achieve these goals,” says Carlson.

In 1997, DMC Mold & Tool invested in VISI-Series solid molding software from Vero International. Jack Thompson from Solid Tooling Solutions was the sales/applications expert that made the initial visit to the facility. Prior to his visit they had solicited a number of solid modeling software packages. They had a similar challenge for each one of the applications experts when they arrived and Jack Thompson’s VISI-Series modeling software was the only one to pass the test.

Recently, it supplemented the suite of software with VISI-Flow, new technology that helps users accurately design molds. They had investigated several other software programs but again found that the VISI-Flow far out paced the competition.

Software benefits: Using VISI-Series, DMC Mold & Tool users can create a full 3D model to show how a mold will be represented. Customers can analyze the model and decide whether or not the mold with perform to their expectations. “Prior to implementing VISI-Flow,” adds Carlson, “we relied on the customer’s knowledge as to where to locate gates and runners, as well as gate and runner sizing. The customer established runner size and location based on what they hoped would be correct. Their expectations were to minimize scrap and maximize quality part potential.

Software benefits: Using VISI-Series, DMC Mold & Tool users can create a full 3D model to show how a mold will be represented. Customers can analyze the model and decide whether or not the mold with perform to their expectations. “Prior to implementing VISI-Flow,” adds Carlson, “we relied on the customer’s knowledge as to where to locate gates and runners, as well as gate and runner sizing. The customer established runner size and location based on what they hoped would be correct. Their expectations were to minimize scrap and maximize quality part potential.

“For many projects, we witnessed our customers struggling to establish mold specifications. Each customer had a ‘go-to’ person who they relied on to decide the best outcome for the mold design. We watched as customers tried to maintain quality, cycle time, and reduce production scrap. Projects suffered because of this traditional methodology. Relying on one person’s expertise is not the proper way to move forward during this economic period,” notes Carlson.

To remain competitive and help its customers, DMC Mold & Tool wanted to change this scenario. Now, using VISI-Flow, DMC Mold & Tool can show them real results prior to tooling. “We can demonstrate if there are any benefits to their runner and gate locations or, what the drawbacks are based on their input. The software provides a full recreation of what the end result will be. VISI-Flow is much more accurate and it also depicts cycle time. Fill accuracy includes a timing element that will help them judge if they are meeting their required cycle time,” Carlson says.

“Using traditional methodology,” says Carlson, “it was a costly measure in time and money to make changes to a tool once it was built. VISI-Flow gives us the ability to make adjustments to the design in a minimal amount of time.”

In today’s fiercely competitive global marketplace, mold makers can’t afford mistakes. With cost consciousness at an all time high, DMC Mold & Tool must be able to show that it can provide more value. Using VISI-Flow, DMC Mold & Tool can offer quality and accurate pricing. “You have to marry everything together. We need the tools to achieve those end goals,” Carlson adds.

{youtube:http://www.youtube.com/watch?v=o6qmzaquQBs}

VISI-Flow projects: Recently, DMC Mold & Tool received a mold for DANA Automotive Products Division that was insert-molded. (An insert-molded mold involves a stamped metal insert that is placed in the mold and plastic is over-molded into it.) The mold was divided into two small plastic sections that were not balanced. Carlson says, “VISI-Flow provided the information we needed to determine runner placement. As a result, we reduced runner size and weight and saved on production scrap by 18 per cent.”

For another VISI-Flow project, DMC Mold & Tool was contracted to build a replacement mold for an existing mold that was not meeting the customers capacity requirements. At first, it worked in the field, but it quickly lost its integrity. As expected, the customer was not satisfied with the tool and approached DMC Mold & Tool to build a replacement.

xxxxxx

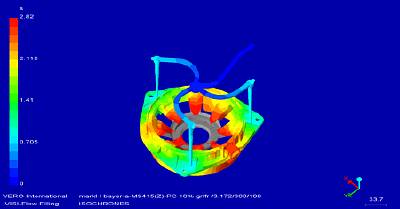

Image shows unbalanced fill condition between three gates all with equal dimensions at the Runner / Drop / Gate. This would result in knit lines and short fill conditions in areas of the part where critical dimensions were necessary.

“We started the project knowing the mold did not fill correctly. Using VISI-Flow, we researched how to improve runners, gates, and cooling. In doing so, we discovered a molded-in stress situation on the part causing a fracture. The custom molder had to adjust their cycle time longer than their quoted cost. We were able to show the customer where the molded-in stress point was located, and we revised the gate placements and sizes. There was tremendous relief on the part of the customer when we provided the VISI-Flow results. The DMC design team’s energy level soared because they knew they prevented a problem from happening,” Carlson reports.

He says that establishing gate locations, gate size, runner locations, and runner sizes are VISI-Flow’s biggest and best performance offerings. “The software is very powerful and fast. It provides customers with an in-depth depiction of the mold design. If we make a change, the customer can see the results of that change.”

xxxxxx

Image shows unbalanced fill condition between large connector & small pad. This would result in an over pack situation on the connector or short fill condition on the pad.

VISI-Flow is also a good sales tool for Carlson. “Besides a good engineering tool, VISI-Flow is an excellent instrument for quoting jobs,” says Carlson. “In this constantly evolving competitive market, we need to have the right tools to satisfy our customers’ needs. We also want to pass along the benefits we are realizing to our customers.”

Learning curve: Carlson’s philosophy on software learning is that it is a continuous process. “Currently, we are only using about 50 percent of the software,” says Carlson. “VISI-Flow is so strong and powerful that it will be a constant learning experience. One of the best outcomes of installing VISI-Flow was that we were profitable right from the start as a result of using it. Due to our prior and ongoing use of VISI-Series software, the learning curve for VISI-Flow was approximately four weeks. End results are only as good as the data you enter. If you are very thorough in data input, you will receive a more accurate result.” Jack Thompson of Solid Tooling Solutions, a VISI-Series and VISI-Flow distributor, implemented the software and provided training.

Software support and product speed: Carlson says VISI-Series and VISI-Flow support is very strong. Vero International provides thorough on-line documentation and tutorials for all its products. Carlson says it’s helpful if users have an engineering background to use the software packages. Vero and Solid Tooling Solutions provide 24/7 telephone support. Carlson says the hotline support is very responsive. The speed of analysis is dependent upon part file size. Analyzing the data can range from two to 10 hours. . Carlson editorial note: “I think VISI-Series and VISI-Flow are underrated software products. New and existing customers constantly ask me ‘What design software do you use?’ When I mention the name VISI, most of the time they are not familiar with it. However, there are other CAD products in the industry that the inquisitive are very familiar with. Prior to implementing VISI-Series nine years ago, we were using one seat of a once very popular, but hard to learn and use package. After we installed VISI-Series and realized the breadth of capabilities, power, and ease of use, we stopped using the other package and let the license lapse. We chose to maintain and grow our VISI-Series system and develop a strong relationship with Jack Thompson at Solid Tooling Solutions and Vero International.

“The most popular CAD providers are hitting the marketplace hard in terms of advertising. However, in terms of product functionality, these products are not meeting customers’ expectations in the long run. We have reviewed most of them and know they all fall significantly short in fulfilling customer requirements. It’s almost to a point of frustration. For instance, when we receive a solid model file rendered using one of the popular solid modeling packages, it typically does not meet industry standards. We are forced to exert a lot of time and effort to repair the file that we are often times faced with telling the customer that it will cost them more money for the project.”

VISI-Series and VISI-Flow

DMC Mold & Tool Corp.

Solid Tooling Solutions