Recent news of GE receiving FAA certification for 3D printed jet engine parts and Airbus incorporating 1000+ 3D printed parts in the A350 XWB aircraft is somewhat at odds with Australian manufacturers’ vision for additive manufacturing.

Professor Milan Brandt, director of RMIT’s Centre for Additive Manufacturing notes that while there had been some AM success stories at this early stage, adoption within Australia’s industry had been slow overall.

“In terms of research we’ve delivered a prototype, we’ve delivered reports, but they have to do their own business case,” he said of some recent cases. “And that’s where things stop.”

Brandt, who will give the keynote address at Manufacturers’ Monthly’s first Factories of The Future event, told us that his facility had never had more enquiries regarding metal-based AM than in the last 12 months.

But the technology – which is transformative as well as much-hyped – hasn’t been something Australian manufacturers had invested in, with business cases of local companies often failing when brought to the board level.

A novel and incredibly promising use of the technology using titanium alloy has been developed by an RMIT research team led by Brandt.

Collaborating with surgeon Professor Peter Choong of St Vincent’s, the team’s Just In Time patient specific implant method replaces bone lost through operations to remove osteosarcoma.

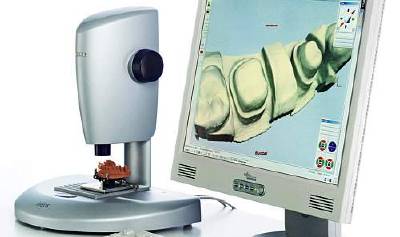

CADinfo.net has reported on surgical and dental applications of additive manufacturing technology for some years now and the collaboration between the medical profession and engineer through technology and processes continues to develop into what will undoubtedly become a mainstream surgical reality in the near future. The idea of having a part manufacturing facility adjacent to a operating theatre is quite a concept.

See full story on manmonthly.com.au

Image courtesy of manmonthly.com.au