FutureBrand ID, headquartered in New York City, is one of the world’s leading integrated industrial design firms specializing in product design, structural packaging, and environmental design. The design firm’s mission is to create three-dimensional product brands by using ergonomic, engineering and manufacturing expertise.

FutureBrand ID, headquartered in New York City, is one of the world’s leading integrated industrial design firms specializing in product design, structural packaging, and environmental design. The design firm’s mission is to create three-dimensional product brands by using ergonomic, engineering and manufacturing expertise.

The firm’s creativity is fuelled by its vast global perspective and network, and realized with the integration of such advanced technological tools as Alias|Wavefront Studio.

The CooperTools Challenge

In a recent project with CooperTools, America’s leading manufacturer of hand tools, FutureBrand ID developed an integrated design solution that redefined the CooperTools adjustable pliers brand in order to better compete with inexpensive drop forged tools imported from Asia.

The resulting product: Duraplyers™, takes advantage of the innovative use of alternative materials and manufacturing processes. The design incorporates an ergonomic shape for superior user performance and meets stringent cost requirements.

Early Research

The design process began with extensive human factors and usage-occasion research to identify consumer needs and wants, as well as competitive pitfalls, through the use of functional stimuli. The findings were the premise of the design criteria for the program.

The design process began with extensive human factors and usage-occasion research to identify consumer needs and wants, as well as competitive pitfalls, through the use of functional stimuli. The findings were the premise of the design criteria for the program.

Where Studio Helped

“Once we had the analysis in hand, our objective was to synthesize the information and begin to quickly produce a design that would fulfill the challenging criteria,” explains Robert Croft, Vice President of FutureBrand ID. “We had to consider ergonomic parameters, material performance, ANSI standards and jaw capacity goals, but we didn’t have the time to move through each stage sequentially. Design, marketing and manufacturing groups needed to deal with the product concept simultaneously.”

Crescent Duraplyers

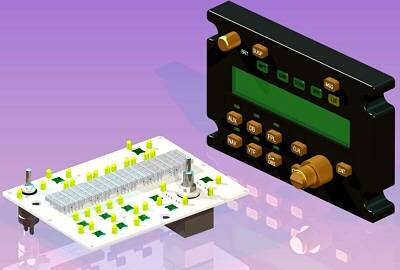

FutureBrand ID found that Alias|Wavefront Studio was the one tool that could give each group the information it needed to move forward. “With Studio renderings, we could see the aesthetics and the ergonomics and also check geometry for the tolerances involved in metal stamping. Everything is already there when you create a design in Studio,” says Croft.

Use in Multiple Platforms

Because each of the product teams worked in a different computing environment, Studio files were transferred to three different platforms. The native PC format was used for industrial design. Renderings were also ported to the MAC environment as PICT files for the marketing department, and as IGES files for manufacturing.

Because each of the product teams worked in a different computing environment, Studio files were transferred to three different platforms. The native PC format was used for industrial design. Renderings were also ported to the MAC environment as PICT files for the marketing department, and as IGES files for manufacturing.

Concurrent Development Saves Weeks of Time

“Because we operated in parallel, we were able to shave weeks, even months of time, off the normal process,” says Croft. “Studio allowed us to meet our product performance and cost objectives – and stay ahead on the time line.”

Successful Rebranding

Today the Crescent Duraplyers™ brand image is visually modernized, plus the product delivers greater load bearing capability, structural strength, and increased performance value. The riveted laminated sheet metal construction is lighter, stronger, and shaped to provide a larger jaw capacity. The safe, non-pinch handle geometry has slide-on ergonomic plastic grips with comfort air channels for a premium quality feel.

Once again FutureBrand ID has successfully integrated strategy, research and technology with a passion and talent for innovation. The result is an outstanding consumer product.

Cooper Tools FutureBrand ID AliasWavefront