Neil Fowler Design Associates Ltd. Of Ontario, Canada designs stamping dies and checking fixtures for the automotive industry. Their designs range from dies that stamp out simple brackets to entire car hoods or chassis panels. Typically, Fowler designs new stamping and checking equipment for each new vehicle design. The company’s main customers include General Motors, Chrysler, and major die and fixture shops in the Detroit and Windsor, Ontario areas. Advertisement Content on this page requires a newer version of Adobe Flash Player.

Neil Fowler Design Associates Ltd. Of Ontario, Canada designs stamping dies and checking fixtures for the automotive industry. Their designs range from dies that stamp out simple brackets to entire car hoods or chassis panels. Typically, Fowler designs new stamping and checking equipment for each new vehicle design. The company’s main customers include General Motors, Chrysler, and major die and fixture shops in the Detroit and Windsor, Ontario areas. Advertisement Content on this page requires a newer version of Adobe Flash Player.

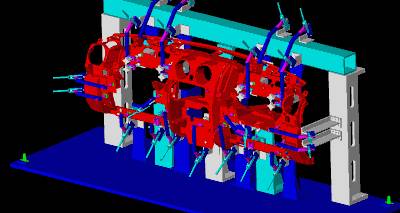

Chris Kelly, Fowler Design senior fixture designer and systems administrator, orders computer systems and software and is responsible for designing attribute and checking fixtures from start to finish including small brackets, full instrument panels, front fascias, and automated fixtures. Each part consists of 2D or full 3D solid modeling design and detailing if required. “We work closely with the manufacturers to make sure that our designs are accurate. If there are mistakes in the design, the fixtures will be built with errors. Addressing those issues late in the production cycle causes expensive set backs.”

Customers demand high quality designs, delivered on time, at the lowest possible price. Kelly says, “We can address quality issues because we aggressively use and research the latest technologies. We know that by using the latest MCAD software helps us develop the highest quality designs.”

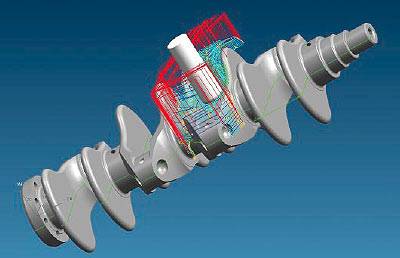

Today, Fowler designers use Autodesk’s Mechanical Desktop software exclusively for their solids and surface modeling needs, as well as to do interference checking. “Car manufacturers and suppliers are increasingly requiring us to provide solid models,” adds Kelly. “Our designs are very complex so the work is challenging. Mechanical Desktop is an integral tool for creating the 3D models we need.” Tight turn around

Today, Fowler designers use Autodesk’s Mechanical Desktop software exclusively for their solids and surface modeling needs, as well as to do interference checking. “Car manufacturers and suppliers are increasingly requiring us to provide solid models,” adds Kelly. “Our designs are very complex so the work is challenging. Mechanical Desktop is an integral tool for creating the 3D models we need.” Tight turn around

Requests for Fowler designs require fast turnarounds–days not weeks. “A request made on a Monday, for instance,” says Kelly, “is 60 percent fulfilled by Friday. This industry is moving at lightening speed. In order to remain competitive, we have to keep up with demands.”

Kelly started using Autodesk’s AutoCAD software in 10th grade and continued using it throughout high school and college. He says the transition from the AutoCAD 2D world to 3D with Mechanical Desktop was very easy. The company implemented Mechanical Desktop at the product’s inception nearly three years ago and continues to find it to be a very strong solution. Besides the software’s extraordinary functionality, Kelly and his team are impressed with the helpful on-line documentation.

“We believe that the visualization capabilities are essential for us,” notes Kelly. “These tools allow us to design as though we were assembling the part on the shop floor. The 3D renderings help us “see” how the parts fit together. Using 2D tools, users are limited to what can actually be visualized. In any industry, missing or interfering parts can cause costly problems downstream. The 3D visualization capabilities facilitate a cleaner or accurate design upfront in the design cycle–saving time and money.”

In addition, Kelly and his colleagues agree that Mechanical Desktop’s interference checking functionality helps them address critical fit and performance issues earlier in the design cycle. “The interference checker automatically points out where problems are or might occur. We can remedy the situation before the design moves downstream.”

Fowler Design recruits designers from the large global population of trained Autodesk software users. “We know that any Autodesk software user can be productive on Mechanical Desktop very quickly,” says Kelly. Mechanical Desktop benefits

Kelly and his team believe they save design time because they can identify errors ahead of time. As each job is completed, it is checked at Fowler Design. Using Mechanical Desktop, Kelly noticed that there are fewer mistakes before designs are checked. “The technology saves time and we’re realizing that our designs have very few, if any, mistakes,” adds Kelly.

Fowler Design is committed to quality. Kelly says that Mechanical Desktop helps the company adhere to its commitment. “We aim to deliver the best quality products to meet customer demands. In a fiercely competitive global marketplace, we know that staying current on technology helps us maintain an edge on our competition,” says Kelly.

Fowler Design is committed to quality. Kelly says that Mechanical Desktop helps the company adhere to its commitment. “We aim to deliver the best quality products to meet customer demands. In a fiercely competitive global marketplace, we know that staying current on technology helps us maintain an edge on our competition,” says Kelly.

As a result of implementing Mechanical Desktop, employee and customer satisfaction has increased. Users are pleased that they have the right tools to create better, higher quality designs. As a result, customers are more than satisfied. Beating skepticism

Recently, Kelly and his team were tasked to design a 3D solid model fixture design for an instrument panel (dashboard) where the radio and other instrumentation are located. “We had to design a fixture to hold the instrument panel in place. The fixture’s clamp had to swing in and out with a moving component and all of this had to fit within a very compact envelope. No 2D software package would have worked for this project because users would not have been able to visualize the moving clamp inside the cramped, opening in the panel,” notes Kelly. Despite skepticism from Fowler management and its customer, Kelly and his team went about designing the fixture in Mechanical Desktop.

“At the customer review meeting, we showed management the isometric views of the new fixture and they were very impressed with the solid models. Using Mechanical Desktop, we convinced the customer that the job was possible. After the fixture was built, it worked perfectly the first time. As a result, our confidence soared and we exceeded our customer’s expectations.”

Prior to implementing Mechanical Desktop, Fowler Design evaluated several packages including CADKEY, Pro/ENGINEER, SolidWorks, thinkdesign, and CATIA. After testing many current solid modelers, Fowler Design chose Mechanical Desktop. They believe it is the best all around package for 3D solids, surfacing, drafting and ease of use.

Fowler Design