A major customer says ‘use these new specifications and ship the new product within 2 ½ months or we’ll give the business to your competitor.’ The job requires a completely new design, with customized sets of 3D models and 2D drawings for multiple suppliers who need to create new injection molds and stamping tools. Pylon of Deerfield Beach, Florida recently faced this challenge. Did Pylon panic?

A major customer says ‘use these new specifications and ship the new product within 2 ½ months or we’ll give the business to your competitor.’ The job requires a completely new design, with customized sets of 3D models and 2D drawings for multiple suppliers who need to create new injection molds and stamping tools. Pylon of Deerfield Beach, Florida recently faced this challenge. Did Pylon panic?

Not really — even though they knew it would be a push. They had been using Solid Edge from Unigraphics Solutions Inc. for about a year and had great confidence in its 3D modeling capabilities. Modeling projects that used to take a week or more, were taking 4-5 hours in Solid Edge. They also have a can-do attitude, a crack design and production team, and lots of experience. Pylon is the leading innovator and producer of windshield wiper blades, inserts and refills in the United States. The company manufactures more than 10 million blades a year for sale in large retail chain stores. Pylon also provides aftermarket blades to automobile dealers nationwide. Founded in 1968, Pylon designed and developed the first universal blade, the first universal refill, and the first see-through packaging.

Facing the Challenge

Pylon’s customers specified new winter blades (the kind with a boot around the blade to prevent ice build-up) for the more aerodynamic windshields of the new larger vehicles in time for a recent winter season. They quickly discovered that an easy fix, making the existing winter blades longer, wouldn’t work because of the size, shape and configuration of the newer windshields. “A totally new design was required”, says Carlos Romero, lead mechanical engineer who has been with Pylon more than three years.

Romero’s team dug in and finished the design phase in 2 1/2 weeks. Romero estimates that if they had been using their previous CAD system, CADKEY, the design would have taken two to three months — if they could have done it all. For example, just the boot (a complex thin wall component with complex surfaces) grew into a 5 megabyte file that had to be modified for every size, for placement in the assembly.

The Solid Edge 3D Advantages

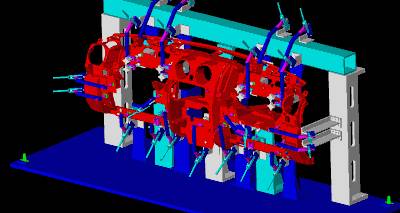

The advantages of Solid Edge for the fast-track winter blade project went far beyond 3D modeling in the design phase. Pylon designs the blades and inserts; paints some metal parts; assembles the final product, and designs the fixtures and machines for assembly and packaging. But they rely on numerous outside suppliers to manufacture the molded and stamped parts. Most of these suppliers use 2D CAD and a few use Pro/Engineer. The IGES and DXF files which were created in Solid Edge and sent to them worked flawlessly. Another time-saving first for Pylon on this project was sending the files back and forth over the Internet.

The advantages of Solid Edge for the fast-track winter blade project went far beyond 3D modeling in the design phase. Pylon designs the blades and inserts; paints some metal parts; assembles the final product, and designs the fixtures and machines for assembly and packaging. But they rely on numerous outside suppliers to manufacture the molded and stamped parts. Most of these suppliers use 2D CAD and a few use Pro/Engineer. The IGES and DXF files which were created in Solid Edge and sent to them worked flawlessly. Another time-saving first for Pylon on this project was sending the files back and forth over the Internet.

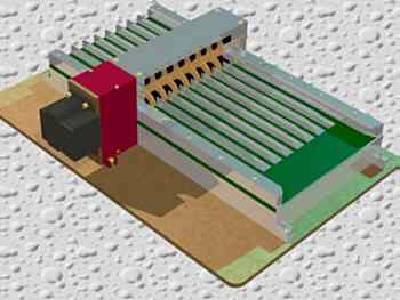

Pylon Manufacturing used Solid Edge from Unigraphics Solutions to design this splitter assembly, a machine which cuts multi blisterpacks of windshield wiper blades into individual packages just prior to shipment to retail outlets.

Tolerance and fit are extremely critical in windshield wiper blades. Working in the assembly environment in Solid Edge meant that interference problems were immediately apparent and discovered before parts were in production or assembly. A long prototyping cycle is a thing of the past, which made a real difference in this fast-track project.

In addition, designing the winter blade boot as a true 3D solid allowed Pylon to change to a more efficient, cost-effective manufacturing process. Previously the synthetic rubber boot was built using a slow, costly, and less-than-accurate dipping process. The Solid Edge files opened the door to a more precise blow molding process.

2D to 3D Transition

Pylon is thrilled with its transition to 3D modeling in Solid Edge. Previously, Pylon was using a 2D program with a little 3D-faking on the side with isometric drawing techniques. Romero found the old Boolean-based modeler awkward in the assembly environment, labor intensive, and not always reliable. A major frustration was getting weeks into a model and then finding out it wouldn’t round or would just blow up.

Because it is so important for the designers at Pylon to work in an assembly environment where tolerances and fit are extremely accurate, Romero knew they needed a good 3D solid modeler. So he made a wish list and started shopping. Base requirements were for a true Windows-native 3D solid modeler that did not require new hardware. It needed to cost less than $5,000, be robust and stable, easy to learn, included strong 2D capabilities and DXF/IGES transfer for working with their suppliers.

Pylon tried Solid Edge, SolidWorks and SDRC Ideas Artisan. Solid Edge was the clear choice based on the strong 2D module and the ease of use and learning. He especially appreciated the menu system not only because it was logical and intuitive for a design engineer, but also because it displayed all the tools needed to perform a specific function in the same place. Productivity with a Capital P

Pylon tried Solid Edge, SolidWorks and SDRC Ideas Artisan. Solid Edge was the clear choice based on the strong 2D module and the ease of use and learning. He especially appreciated the menu system not only because it was logical and intuitive for a design engineer, but also because it displayed all the tools needed to perform a specific function in the same place. Productivity with a Capital P

Two years later, Romero is still positive he made the right decision. Romero describes the responsive, hands-on support they received from Solid Edge, especially from the local Solid Edge VAR, Allied Technology Corp. South Florida. He tells about how easy it is to re-use old geometry by bringing “old” 2D CADKEY part files and then using sketch and extrude to create new 3D geometry. But most of all he raves about Productivity — with a capital P. The winter blade project is a prime example!